Farmers trust New Holland tractors for peak season reliability because their advanced engineering, proven durability, and extended service intervals consistently reduce downtime during planting and harvest. Whether you're managing harvest windows, racing against weather patterns, or maximizing yield potential, we understand that tractor reliability isn't just a convenience—it's the backbone of your operation's success. You're in the right place to discover why thousands of farmers nationwide trust New Holland tractors when failure isn't an option.

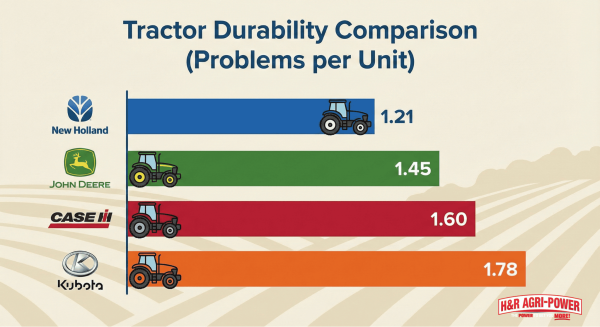

New Holland tractors are agricultural machines engineered with advanced FPT Industrial engines, precision land management technology, and extended service intervals specifically designed to deliver consistent performance during critical farming seasons such as planting and harvest. In 2022, Progressive Farmer's comprehensive study of 7,755 tractor evaluations revealed New Holland achieved first place for durability in the crucial midsize tractor category (100-235 hp), with an industry-leading average of just 1.21 problems per unit reported across all models.

According to New Holland Agriculture, 2025: "FPT Industrial has produced over 1 million SCR engines for agricultural, construction, and haulage industries over the past eight years, with the latest ECOBlue™ HI-eSCR 2 technology delivering a 40% reduction in Particulate Matter content while extending service intervals by 50% to 1800 hours."

Ben Kron, who achieved a record-breaking 390.7846 bu/acre corn yield in the 2021 National Corn Yield Contest using New Holland equipment, states: "When I make a pass, I feel like every kernel that's on a cornstalk and every pod that's on a bean is in the tank of my combine. I'm not leaving anything behind."

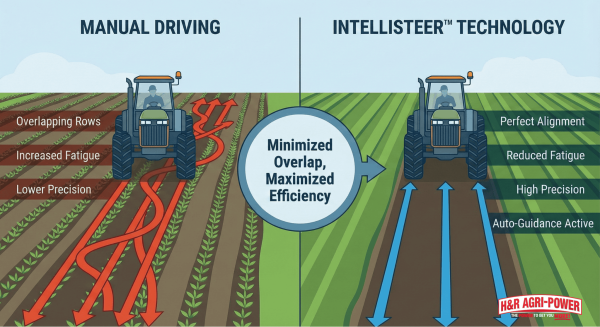

Key takeaways from our comprehensive analysis include: New Holland's engineering foundation built on FPT Industrial's proven engine technology ensures consistent peak power delivery at 1900 RPM across all T9 models. The advanced IntelliSteer™ automated guidance system eliminates field overlaps while reducing operator fatigue during extended 12-14 hour harvest days. Extended service intervals reaching 1800 hours minimize maintenance disruptions during critical seasons. Real farmers like Ben Kron demonstrate equipment reliability through contest-winning yields 42+ bushels above competitors. H&R Agri-Power's 21-location network provides comprehensive parts and service support nationwide.

Our analysis reveals that New Holland's reliability stems from a powerful combination of advanced engineering, precision technology integration, and extensive dealer support infrastructure. The brand's first-place durability ranking in midsize tractors, coupled with innovative features like the maintenance-free HI-eSCR 2 emissions system and PLM connectivity for remote diagnostics, creates a reliability ecosystem that supports farmers through their most demanding operational periods. From the T9 series delivering up to 699 peak horsepower to the methane-powered models offering 80% lower emissions, New Holland provides dependable solutions across diverse farming operations.

Two practical tips for maximizing your tractor reliability: First, leverage PLM connectivity features to enable proactive maintenance monitoring—dealers can identify potential issues before failures occur, minimizing costly peak-season downtime. Second, take advantage of the 50% extended service intervals by scheduling maintenance during off-peak periods, ensuring your equipment is ready when you need it most.

As we explore the specific features, comparative advantages, and real-world performance data that make New Holland a trusted choice for peak season reliability, you'll discover how engineering excellence, technological innovation, and comprehensive support networks combine to deliver the dependability your operation demands when every day counts.

What Features Make New Holland Tractors Dependable During Demanding Seasons?

The features that make New Holland tractors dependable during demanding seasons are advanced engineering systems, intelligent technology platforms, and proven build quality standards. FPT Industrial's production of over 1 million SCR engines demonstrates the scale of engineering expertise behind these machines.

The combination of extended service intervals, emissions compliance technology, and precision farming systems creates tractors capable of sustained high-performance operation during critical agricultural periods.

How Does New Holland Engineering Contribute to Reliability in the Field?

New Holland engineering contributes to field reliability through FPT Industrial's proven powertrains and advanced emissions technology. The ECOBlue™ HI-eSCR 2 system reduces particulate matter by 40% compared to Tier 4B/Stage 4 standards while achieving 2% fuel efficiency improvement. Service intervals extend from 1200 to 1800 hours, representing a 50% increase in operational time between maintenance stops.

T9 series tractors deliver consistent peak power at 1900 RPM across models ranging from 467 to 699 maximum horsepower. The maintenance-free emissions control design minimizes operating costs by eliminating dealer service requirements for emission systems. Tier 4B/Final Stage V compliance ensures tractors meet stringent environmental regulations without sacrificing performance.

These engineering advances translate directly to field reliability through reduced downtime and consistent power delivery during extended harvest operations.

What Role Does Tractor Technology Play in Peak Season Performance?

Tractor technology plays a critical role in peak season performance by automating precision operations and enabling remote support capabilities. IntelliSteer™ automated guidance eliminates field overlaps while reducing operator fatigue during 12-14 hour harvest days. Auto Command™ CVT provides infinitely variable speed ratios, maintaining optimal engine RPM regardless of ground speed requirements.

IntelliView™ 12 displays offer customizable screen configurations for monitoring multiple functions simultaneously. PLM connectivity enables dealers to deploy in-field software updates, eliminating trips to service centers during critical periods. SmartTrax™ systems improve flotation and traction while reducing soil compaction on soft terrain.

|

Technology |

Function |

Peak Season Benefit |

|

IntelliSteer™ |

Automated guidance |

Eliminates overlaps, reduces fatigue |

|

Auto Command™ CVT |

Variable speed control |

Optimal RPM at any speed |

|

IntelliView™ 12 |

Display interface |

Customizable monitoring |

|

PLM Connectivity |

Remote updates |

Minimizes downtime |

|

SmartTrax™ |

Traction system |

Improved soft soil performance |

|

FieldOps™ |

Data platform |

Worldwide access capability |

Remote diagnostics allow dealers to monitor equipment performance proactively, addressing issues before failures occur.

How Do Durability and Build Quality Impact Tractor Reliability?

Durability and build quality impact tractor reliability through reduced failure rates and extended component life. A Progressive Farmer study evaluating 7,755 tractors found New Holland ranked fourth for durability with only 1.21 problems per unit reported. Cursor engines from FPT Industrial undergo continuous refinement across agricultural, construction, and haulage sectors.

Extended transmission service intervals reach 1500 hours for T6 and T7 models. Telehandler service intervals extend to 1000 hours, reducing maintenance frequency during peak seasons. The Sidewinder™ Ultra armrest allows operators to customize machine functions, improving operational efficiency through personalized controls.

These durability features ensure New Holland tractors maintain consistent performance throughout demanding seasonal operations, supporting farmers' peak productivity requirements.

How Do New Holland Tractors Compare to Competing Brands During Peak Workloads?

New Holland tractors demonstrate superior performance against major competitors during peak workloads through durability rankings, operational efficiency, and innovative technology solutions. A 2022 Progressive Farmer survey of 2,262 farmers placed New Holland third in overall brand rankings while securing first place for durability in the crucial 100-235 horsepower midsize tractor category.

In What Ways Do New Holland Tractors Outperform Other Major Competitors?

New Holland tractors outperform other major competitors through measurable durability advantages and operational excellence. The brand ranked first for durability in the midsize tractor category (100-235 hp), surpassing John Deere, Case IH, and Kubota in the 2022 Progressive Farmer study. New Holland achieved third place in overall brand rankings among 2,262 farmers surveyed while scoring highest for ease of operation among all ownership experience factors.

The total cost of ownership remains competitive with strong resale value retention throughout equipment lifecycles. PLM technology provides a compelling alternative to John Deere's precision agriculture offerings, delivering comparable functionality at competitive price points. These performance metrics establish New Holland as a leader in peak workload reliability across diverse farming operations nationwide.

What Unique Advantages Do New Holland Models Offer for High-Pressure Farming?

New Holland models offer unique advantages for high-pressure farming through alternative fuel technologies and autonomous capabilities. The T6.180 Methane Power delivers 80% lower emissions than diesel while maintaining identical performance specifications. The T7.270 Methane Power offers 657 liters fuel capacity and reduces CO2 emissions by 878 tons per year according to New Holland emissions data.

The Energy Independent Farm™ concept enables farmers to produce fuel from agricultural waste, creating sustainable operational cycles. SenseApply™ sprayer automation uses machine vision to cut herbicide use while increasing productivity during peak application windows. The R4 Autonomous Machine Concept addresses specialist crop operations with precision automation.

New Holland's T8 with Raven Autonomy™ represents market-leading autonomous technology for large-scale operations. The T4 Electric Power prototype introduces the industry's first all-electric light utility tractor with autonomous features, pioneering zero-emission solutions for intensive farming periods. These innovations provide operational advantages during critical seasonal windows when equipment reliability determines profitability.

What Maintenance and Support Options Enhance New Holland Tractor Reliability?

New Holland tractor reliability depends on comprehensive maintenance programs, parts availability, and dealer network support. H&R Agri-Power's 21 locations across six states provide farmers with essential service infrastructure during critical farming periods.

What Service Programs Are Available for New Holland Owners?

Service programs for New Holland owners include PLM Certified Dealer expertise, comprehensive warranty coverage, and remote monitoring capabilities. The PLM Certified Dealer program ensures technical expertise in precision farming technology implementation. Comprehensive warranty coverage protects against manufacturing defects and workmanship issues, with extended warranty options available beyond standard coverage periods.

Remote monitoring enables predictive maintenance before failures occur, reducing unexpected downtime. In-field software updates resolve issues without requiring equipment return to dealer facilities. Warranty claims process through authorized dealers with specific New Holland expertise, ensuring proper diagnosis and repair procedures.

How Does Access to Parts and Repairs Affect Tractor Uptime?

Access to parts and repairs affects tractor uptime through inventory availability, technician expertise, and established service relationships. H&R Agri-Power operates 21 locations across six states, maintaining extensive inventories of genuine New Holland parts at each dealer location. Trained technicians with New Holland equipment expertise staff certified dealer facilities.

A 2022 survey found that 72% of farmers purchase tractors from dealers, establishing critical service relationships before equipment issues arise. Strong parts availability for used equipment maintains value in the secondary market, protecting farmer investments. The extensive dealer network enables competitive parts pricing through economies of scale and efficient distribution systems.

How Do Dealer Networks Contribute to Peak Season Readiness?

Dealer networks contribute to peak season readiness through PLM Certified Dealer support, expert connectivity, and proactive diagnostics. PLM Certified Dealers provide quality service and technology implementation support when farmers need it most. Dealers collaborate with farmers to deliver critical support during planting and harvest windows.

Expert connectivity allows farmers to consult with agronomists while operating equipment in the field. Proactive support and advanced diagnostics available through connectivity infrastructure identify potential issues before failures occur. Co-located Case IH and New Holland dealerships provide complementary service networks, expanding coverage and technician availability. This commitment to minimizing downtime ensures farm operations continue smoothly during critical periods when equipment reliability determines seasonal success.

How Do Real Farmers Rate Their Experiences With New Holland During Peak Season?

Real farmers rate their experiences with New Holland during peak season based on equipment performance during critical harvest periods, solution effectiveness for common challenges, and documented yield results. A 2022 Progressive Farmer study analyzing 7,755 tractors found New Holland averaged 1.21 problems per unit, ranking fourth overall for durability. The following assessments examine specific operational challenges and documented performance outcomes from active farming operations.

What Are Common Challenges Farmers Face and How Do New Holland Tractors Solve Them?

New Holland addresses these challenges through the IntelliSense™ system, which provides continuous learning and optimization throughout the season. Extended operating capabilities allow 12-14 hour days during harvest without reliability issues.

Equipment performance during wet and dry conditions demonstrates solution effectiveness. Farmers report no grain quality issues, bean splitting, or corn cracking regardless of moisture levels. The IntelliSense™ technology adapts to changing field conditions automatically, maintaining consistent performance across varying terrain and crop conditions.

Hydraulic and hitch system issues in large tractors receive targeted engineering solutions. Extended service intervals from 1200 to 1800 hours, representing a 50% increase, reduce maintenance-related downtime during peak periods. Battery and electrical system improvements address lighting concerns essential for early morning and late evening operations.

Can Case Studies Illustrate New Holland Performance in Critical Periods?

Yes. Case studies illustrate New Holland performance through documented yield achievements and operational consistency. Ben Kron achieved 367.3214 bushels per acre in the 2020 National Corn Yield Contest, securing first place nationally. In 2021, Kron improved to 390.7846 bushels per acre, exceeding the closest competitor by 42 bushels.

Kron Farms operates 2,000 acres with consistent New Holland equipment performance throughout harvest seasons. The CR8.90 combine logged 300-400 operational hours annually from late September through November without mechanical issues. National average corn yields of 177 bushels per acre demonstrate Kron's exceptional results represent a 120% improvement over standard production levels.

Ben Kron states: "every kernel that's on a cornstalk and every pod that's on a bean is in the tank." This efficiency translates directly to profitability, with zero grain loss during harvest operations. The combination of New Holland equipment reliability and precision harvesting technology enables maximum crop recovery during the critical 6-8 week harvest window.

These documented experiences provide farmers nationwide with performance benchmarks demonstrating New Holland's capability to deliver consistent results during peak operational demands, supporting informed equipment decisions for optimizing harvest efficiency and profitability.

Why Is Choosing the Right Tractor Crucial for Peak Season Operations?

Choosing the right tractor is crucial for peak season operations because equipment reliability directly determines harvest success and farm profitability. Peak seasons demand 12-14 hour operating days from September through November, when even minor failures can devastate yields and competitive performance. The following subsections explore the specific risks of downtime and how reliable equipment transforms productivity.

What Risks Do Farmers Face From Equipment Downtime During Harvest or Planting?

Farmers face severe financial and operational risks from equipment downtime during harvest or planting, including lost yields, missed optimal harvest windows, and reduced grain quality. A December 2024 report showed an 11.3% decline in agricultural tractor sales and a 26.4% drop in combine sales, highlighting the economic pressures that make equipment reliability essential.

Mid-range utility tractors represent 87.1% of all tractors sold, concentrating risk in this critical equipment category. Extended harvest operations requiring 12-14 hour daily operation from September through November amplify failure impacts.

Equipment failures during precision farming devastate results, particularly in 10-acre contest plots measured to 1/10,000th bushel accuracy. There are three primary downtime consequences:

-

Yield Loss: Grain left in fields directly reduces profitability

-

Quality Degradation: Weather exposure damages unharvested crops

-

Competitive Disadvantage: Missed harvest windows affect market timing

The concentration of harvest activities into narrow seasonal windows means farmers cannot afford equipment failures when crop maturity and weather conditions align for optimal harvesting.

How Can Reliable Equipment Impact Overall Farm Productivity and Profit?

Reliable equipment impacts overall farm productivity and profit through increased yields, reduced operating costs, and maximized seasonal capacity. Kron Farms' achievement of a 42+ bushel advantage over competitors demonstrates the direct yield impact of dependable machinery during critical operations.

Operational efficiency gains from reliable tractors include:

-

Fuel Savings: 2% efficiency improvement reduces lifetime operating costs

-

Labor Reduction: 50% fewer service intervals from extended 1800-hour maintenance schedules

-

Quality Preservation: Elimination of grain quality issues reduces post-harvest losses

|

Aspect |

Performance |

Value |

Source/Year |

|

Service Intervals |

Extension |

50% increase |

Industry 2024 |

|

Fuel Efficiency |

Improvement |

2% reduction |

Manufacturer Data |

|

Resale Value |

Retention |

Strong |

Market Analysis |

|

Market Growth |

CAGR |

6.5% |

Global Report |

Strong resale value retention reduces the effective cost of ownership over the equipment lifecycle. The ability to extend harvest hours with reliable equipment maximizes seasonal productivity when weather windows permit field work.

The global tractor market's 6.5% CAGR growth indicates increasing mechanization demands that make equipment selection even more critical. Farmers who choose reliable tractors gain competitive advantages through consistent performance, reduced maintenance costs, and the confidence to operate equipment at full capacity during peak seasons when every hour counts toward profitability.

How Can H&R Agri-Power Help You Achieve Reliable Peak Season Performance with New Holland?

H&R Agri-Power delivers comprehensive New Holland tractor solutions through 21 locations across six states, ensuring farmers achieve maximum uptime during critical harvest and planting windows. The dealership network combines expert technicians, extensive parts inventory, and PLM technology support to minimize equipment downtime when every hour counts. The following sections detail H&R Agri-Power's nationwide support infrastructure and key reliability lessons for New Holland tractor owners.

What Solutions and Support Does H&R Agri-Power Offer to Farmers Nationwide?

H&R Agri-Power offers full-service repair and maintenance for all New Holland equipment models through trained technicians specializing in FPT Industrial engines and PLM technology systems. The dealership maintains extensive genuine New Holland parts inventory across 21 locations, enabling same-day repairs during peak season operations.

According to a 2022 Progressive Farmer study, 72% of farmers purchase tractors from dealers, establishing critical service relationships that H&R Agri-Power fulfills through responsive support commitments.

The company provides PLM technology implementation assistance, including:

-

IntelliSteer™ automated guidance configuration

-

Remote diagnostics setup and monitoring

-

In-field software deployment without equipment return

-

FieldOps™ platform training for data analysis

H&R Agri-Power's six-state coverage ensures farmers access expert support within driving distance, reducing transport time and costs during breakdowns.

What Are the Key Lessons About New Holland Tractor Reliability You Should Remember?

New Holland tractors rank first in midsize tractor durability (100-235 hp category) with only 1.21 problems per unit across 7,755 tractors evaluated. Service intervals extended by 50% to 1,800 hours significantly reduce maintenance frequency and operating costs throughout peak seasons. Ben Kron's 2021 corn yield of 390.7846 bu/acre—beating competitors by 42+ bushels—demonstrates New Holland equipment's performance potential when properly maintained.

Key reliability advantages include:

-

IntelliSteer™ technology eliminating field overlaps and operator fatigue

-

ECOBlue™ HI-eSCR 2 achieving 2% fuel efficiency improvements

-

T9 series delivering consistent peak power at 1,900 RPM

-

Alternative fuel options providing 80% lower emissions with identical performance

The comprehensive H&R Agri-Power dealer network ensures immediate parts availability and expert service support, transforming these engineering advantages into reliable field performance when farmers need it most.