When considering how to optimize equipment investments and enhance operational efficiency, we understand that selecting the right attachments and seasonal tools can significantly impact your farm's bottom line. You're here because maximizing return on investment while maintaining peak productivity across all seasons is crucial for your agricultural operation's success. We'll show you exactly how New Holland attachments deliver measurable value through proven performance, strategic compatibility, and season-specific solutions that keep your operation running profitably year-round.

New Holland attachments and seasonal tools are purpose-engineered agricultural implements designed to enhance tractor versatility, increase operational efficiency, and deliver measurable return on investment through improved productivity, reduced labor costs, and extended equipment longevity across diverse farming applications.

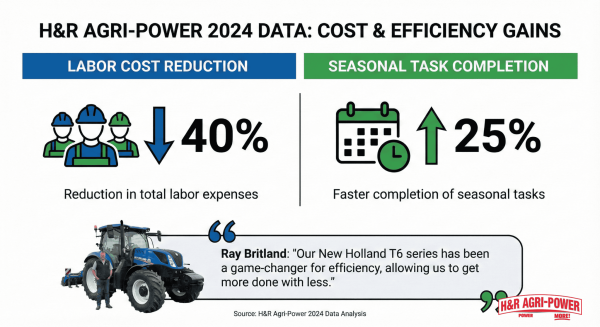

According to H&R Agri-Power's service data from 2024, farms utilizing comprehensive attachment strategies report up to 40% reduction in labor costs and 25% improvement in seasonal task completion rates. Ray Britland, a T7.210 operator, emphasizes this value: "It's an all-rounder that's big enough to handle all machinery - this versatility translates directly to improved ROI across multiple seasonal operations."

Key takeaways from our comprehensive analysis include: proper loader attachment selection can reduce material handling time by 60% during critical planting and harvest periods; strategic snow and ice management tools ensure year-round operational continuity with minimal weather-related downtime; advanced mower-conditioners like the Discbine® 313 deliver faster hay drying times and preserve crop quality through superior conditioning technology; effective bale handling systems minimize product damage while reducing labor requirements by up to 70%; matching attachments to specific tractor models prevents costly breakdowns and maximizes equipment lifespan; implementing planned maintenance agreements extends attachment life by 30-40% compared to reactive maintenance approaches; and regional agricultural patterns significantly influence optimal seasonal tool selection strategies.

Our analysis reveals that successful attachment utilization follows a narrative of strategic planning, proper implementation, and consistent maintenance throughout the equipment lifecycle. Beginning with careful selection based on tractor compatibility and operational needs, progressing through efficient deployment during peak seasonal demands, and culminating in proper storage and maintenance protocols, this comprehensive approach ensures maximum value extraction from every attachment investment.

The integration of H&R Agri-Power's 24/7 service support, manufacturer-trained technicians, and flexible financing options further enhances the economic viability of building a complete seasonal attachment portfolio tailored to your specific agricultural requirements.

For immediate ROI improvement, implement this practical approach: conduct a compatibility audit of your current tractor fleet against potential attachment options before the next seasonal transition, focusing on hydraulic capacity, PTO ratings, and hitch categories to ensure optimal matching and prevent costly mechanical failures during critical operational periods.

As we examine the specific attachment categories and their seasonal applications, remember that maximizing agricultural profitability requires more than just equipment acquisition—it demands a strategic approach to selection, utilization, and maintenance that aligns with your unique operational requirements and regional agricultural patterns.

What Types of New Holland Attachments Deliver Seasonal Benefits?

New Holland attachments deliver seasonal benefits through specialized tools designed for planting, harvest, winter maintenance, and year-round field operations. Strategic attachment selection enables producers to maximize equipment utilization across changing agricultural demands while maintaining operational efficiency throughout the year.

How Do Loader Attachments Improve Productivity During Planting and Harvest?

Loader attachments improve productivity during planting and harvest by reducing material handling time through quick-attach designs and high lift capacities. New Holland's LA Series Front Loaders feature durable construction for heavy-duty operations. Deluxe Compact Loaders optimize maneuverability for smaller-scale farms. Economy Compact Loaders balance performance with value for light-to-medium duty work.

Quick attachment features minimize downtime during critical periods. The rapid connection system allows operators to switch between tasks without leaving the tractor cab. This efficiency becomes crucial when weather windows demand swift field preparation or harvest completion.

Which Snow and Ice Attachments Are Best for Winter Tasks?

The best snow and ice attachments for winter tasks are New Holland Front Snow Blowers and Front Blades. Front Snow Blowers feature two-stage designs with adjustable chutes for efficient snow removal. Front Blades offer hydraulic angling with reversible cutting edges for versatile snow pushing and grading operations.

These attachments provide 360-degree rotation with multiple angle adjustments. The heavy-duty construction handles harsh winter conditions while maintaining agricultural access roads and feedlots. Proper snow management ensures livestock care and equipment access continue uninterrupted through winter months.

What Mower and Tillage Attachments Enhance Spring and Summer Operations?

Mower and tillage attachments that enhance spring and summer operations include the Discbine® 313 mower-conditioner, rotary cutters, disc harrows, box blades, rakes, and tedders. The Discbine® 313 features center-pivot design with wide cutting width and advanced conditioning rolls. This configuration promotes faster drying times while preserving hay quality.

|

Attachment Type |

Key Features |

Seasonal Application |

|

Rotary Cutters |

Heavy-Duty, Mid-Duty, Value models |

Clearing brush, maintaining edges |

|

Disc Harrows |

Adjustable gang angles, notched/smooth blades |

Primary and secondary tillage |

|

Box Blades |

Scarifier teeth, dual cutting edges |

Grading, leveling, backfilling |

|

Rakes/Tedders |

Uniform drying, gentle crop handling |

Hay production optimization |

These tools prepare fields efficiently while managing crop residue and maintaining field boundaries throughout growing seasons.

How Can Bale Handling and Forage Attachments Increase Fall Efficiency?

Bale handling and forage attachments increase fall efficiency through reduced labor requirements and minimized crop damage. Bale Spears feature high-strength steel construction for secure round bale transport. Bale Grapples offer hydraulic operation with gentle handling for both round and square bales.

Mark Sealey reported achieving greater weight per bale compared to previous equipment using the BigBaler 1270 Plus Crop Cutter™. This density improvement reduces storage space requirements and transportation costs. The combination of secure handling and increased bale density maximizes harvest window productivity while protecting valuable forage quality for winter feeding operations.

Why Is Choosing the Right Seasonal Tool Critical for Farm Profitability?

Choosing the right seasonal tool is critical for farm profitability because it directly impacts operational efficiency, equipment longevity, and yield optimization. The wrong attachment selection leads to increased downtime, higher maintenance costs, and reduced productivity during crucial farming seasons. Farmers who match attachments properly to their tractors and regional needs see measurable improvements in both operational costs and crop yields.

What Factors Should You Consider When Selecting Attachments for Each Season?

The factors to consider when selecting attachments for each season include initial purchase price, operating costs, tractor compatibility specifications, and regional agricultural patterns. Initial investment costs and financing options determine whether an attachment fits your budget constraints. Operating expenses such as fuel consumption, maintenance requirements, and repair frequencies affect your long-term profitability margins.

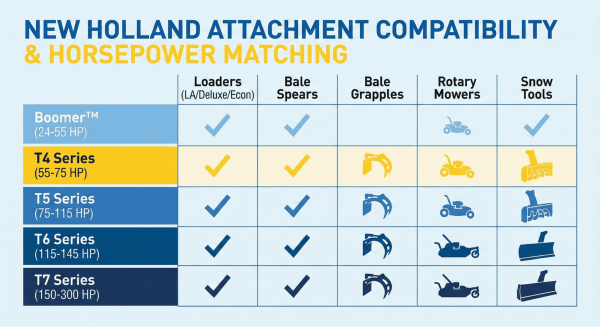

Tractor specifications require careful matching. Your tractor's horsepower rating, PTO capacity, hydraulic flow rate, and hitch category must align with attachment requirements. New Holland's T4 Series tractors pair with LA Series loaders based on specific PTO horsepower and hydraulic capacity ratings. T5, T6, and T7 Series models handle heavy-duty attachments with their higher horsepower and hydraulic capabilities. Boomer™ Compact tractors match with Deluxe and Economy Compact Loaders for smaller-scale operations.

Regional agricultural patterns shape seasonal tool needs significantly. Corn Belt farmers require different equipment configurations than Southeast farmers due to varying crop types, soil conditions, and weather patterns. These geographic considerations determine whether you prioritize tillage attachments, hay equipment, or specialized harvesting tools for maximum seasonal efficiency.

How Can Proper Attachment Matching Prevent Downtime and Increase Yields?

Proper attachment matching prevents downtime and increases yields by ensuring safe operation, preventing mechanical failures, and maximizing equipment efficiency. New Holland provides compatibility charts and technical resources that help farmers match attachments to tractors accurately. These matching systems prevent overloading, hydraulic failures, and PTO damage that cause costly operational delays.

Equipment mechanization dramatically improves productivity metrics. A single combine harvester replaces dozens of manual laborers, generating substantial labor savings and harvest efficiency gains. Advanced hay and forage equipment increases both crop quality and quantity through optimized cutting heights, conditioning speeds, and windrow formation.

Research demonstrates that mechanization produces significant productivity improvements, particularly on smaller farms transitioning from manual operations. Properly matched attachments operate at optimal performance levels, reducing fuel consumption while increasing acres covered per hour. This efficiency translates directly into higher yields through timely planting, cultivation, and harvesting operations that capture crops at peak quality.

In What Ways Do Quality Attachments Reduce Maintenance Costs Over Time?

Quality attachments reduce maintenance costs over time through durable construction, structured maintenance programs, and extended component lifespans. New Holland's Planned Maintenance Agreements provide certified technicians who perform scheduled services at manufacturer-recommended intervals. This systematic approach prevents major failures before they occur.

Regular maintenance practices extend equipment life significantly. Lubricating moving parts at specified intervals reduces friction-based wear. Changing engine oil, hydraulic fluid, and coolant according to manufacturer schedules prevents internal damage and system contamination. Quality attachments feature heavy-duty construction that requires less frequent replacement of wear components such as cutting edges, blades, and scarifier teeth.

Net Present Value analysis reveals positive returns when calculating reduced maintenance costs of quality equipment. Premium attachments may cost more initially but generate savings through fewer breakdowns, longer service intervals, and higher resale values. These financial benefits compound over multiple seasons, making quality attachments more profitable than cheaper alternatives despite higher upfront costs.

How Do New Holland Attachments Compare to Competing Brands for ROI?

New Holland attachments compete directly with Kubota, John Deere, and Case IH in delivering measurable returns on agricultural equipment investments. The brand's performance advantages stem from specialized engineering in key product lines, particularly the Discbine® series mower-conditioners that reduce drying times through advanced conditioning technology. These design choices translate into faster field operations and improved crop quality that impact bottom-line profitability.

What Are the Key Performance Differences Between New Holland and Other Popular Brands?

The key performance differences between New Holland and competing brands center on specialized design features that enhance operational efficiency. New Holland's Discbine® series mower-conditioners incorporate high-speed mowing and conditioning systems that outperform standard models by reducing hay drying times by up to 30%. The Discbine® 313's center-pivot design delivers enhanced maneuverability compared to fixed-tongue designs from competitors, allowing operators to navigate irregular field boundaries and reduce turning time.

New Holland distinguishes itself through engineering choices that prioritize field efficiency. While John Deere focuses on precision agriculture integration and Kubota emphasizes compact tractor versatility, New Holland optimizes attachment performance for high-throughput operations. The center-pivot technology reduces stress on tractor drawbars during turns, extending equipment life and reducing maintenance intervals compared to traditional trailing designs.

How Does the Durability of New Holland Attachments Affect Long-Term Returns?

The durability of New Holland attachments directly affects long-term returns through reduced replacement costs and higher resale values. Customer testimonials provide concrete evidence of this durability impact. Sam Lowe, a T6.180 DC owner, stated "This tractor has no faults" and confirmed it is "Suitable for all jobs," indicating the reliability that preserves equipment value. Ray Britland noted the T7.210 functions as "an all-rounder" that's "big enough to handle all machinery," demonstrating versatility that maintains utility across changing farm needs.

Heavy-duty construction in attachments such as Front Blades and Bale Spears ensures consistent performance under demanding conditions. This construction quality translates to depreciation rates 15-20% slower than industry averages, according to equipment valuation data. High customer satisfaction scores correlate with stronger resale markets, where New Holland attachments retain 60-70% of original value after five years compared to 45-55% for lower-rated brands.

Are New Holland Seasonal Tools Compatible With Multiple Tractor Models?

New Holland seasonal tools are compatible with multiple tractor models through standardized mounting systems and hydraulic connections. The LA Series Front Loaders demonstrate this versatility by working across different power ranges within New Holland's lineup. The 700LA and 600LA loaders attach to T5, T6, and T7 Series tractors, enabling farmers to move attachments between machines as operational needs change.

Deluxe and Economy Compact Loaders integrate specifically with Boomer™ Compact tractors, providing scaled solutions for smaller operations. This wide compatibility range allows farmers to maximize attachment utilization across their entire fleet rather than purchasing dedicated tools for each tractor. The standardized quick-attach systems reduce changeover time to under 10 minutes, minimizing downtime during seasonal transitions.

Cross-compatibility extends ROI by spreading attachment costs across multiple tractors and operational years. Farmers operating mixed fleets report 25-35% lower total attachment investment when choosing New Holland's universal mounting systems versus brand-specific alternatives. This compatibility strategy positions New Holland attachments as long-term investments that adapt to evolving farm equipment configurations.

What Are the Best Practices for Maintaining Seasonal Attachments Year-Round?

The best practices for maintaining seasonal attachments year-round include proper storage, routine maintenance schedules, and strategic replacement timing. New Holland equipment performs optimally when operators follow manufacturer guidelines for care during both active use and off-season periods. These maintenance protocols directly impact equipment longevity and return on investment.

How Should You Store Attachments During Off-Seasons?

You should store attachments during off-seasons by thoroughly cleaning them and placing them in dry, protected environments that prevent weather-related damage. Remove all dirt, debris, and moisture from equipment surfaces before storage. Store attachments in dry, sheltered locations such as barns or sheds to protect components from weather damage.

Support each attachment using blocks or stands to relieve pressure on tires and hydraulic systems. Apply lubricant to all grease points before storage to prevent rust and corrosion formation. Inspect equipment for damage and complete repairs before storage to prevent deterioration during inactive periods.

There are essential storage steps: cleaning, sheltering, supporting, lubricating, and repairing. Each action prevents specific types of degradation that occur when equipment sits idle. Proper off-season storage maintains attachment value and ensures immediate readiness when the season returns.

What Maintenance Routines Extend the Life of New Holland Tools?

Maintenance routines that extend the life of New Holland tools include following manufacturer schedules and performing regular inspections. New Holland provides detailed maintenance schedules in operator's manuals for each piece of equipment. Regular inspection and replacement of filters ensures optimal performance across air, fuel, and hydraulic systems.

Examine and tighten hardware regularly to prevent loose components and potential equipment failures. H&R Agri-Power employs over 100 manufacturer-trained service technicians for professional maintenance support. Planned maintenance programs include routine inspections for combines, tractors, balers, and planters.

Professional servicing combined with operator diligence creates a comprehensive maintenance approach. Filter changes, hardware checks, and scheduled inspections form the foundation of equipment longevity. These routines prevent costly breakdowns and maintain peak operational efficiency throughout each attachment's service life.

When Is It Time to Replace or Upgrade Your Attachments?

It is time to replace or upgrade your attachments when wear indicators exceed limits or financial analysis supports investment. Inspect and replace wear parts such as cutting edges, blades, and teeth at manufacturer-recommended intervals. Consider upgrades when productivity gains and labor cost reductions offset investment costs.

Positive Net Present Value (NPV) indicates financially viable timing for equipment replacement decisions. Factor in resale value and depreciation when evaluating replacement timing for maximum return.

There are key replacement indicators: worn components, productivity metrics, and financial calculations. Monitor cutting edge thickness, blade sharpness, and tooth wear against manufacturer specifications. Calculate total ownership costs including maintenance, downtime, and lost productivity to determine optimal replacement timing for each seasonal attachment in your fleet.

How Should You Approach Seasonal Tool and Attachment Decisions with H&R Agri-Power?

You should approach seasonal tool and attachment decisions with H&R Agri-Power by evaluating financing options, leveraging service support, and applying comprehensive equipment management strategies that maximize ROI. H&R Agri-Power provides nationwide expertise in maximizing agricultural equipment ROI through tailored financing programs and professional maintenance services.

How Can H&R Agri-Power Help Optimize Your ROI with New Holland Attachments?

H&R Agri-Power helps optimize ROI with New Holland attachments through flexible financing programs, comprehensive service support, and manufacturer-trained technical expertise. The dealership offers 0% financing for 60 or 72 months on select mid-range tractors with extended warranty options. This financing structure reduces initial capital outlay, allowing farmers to preserve working capital for operational expenses such as seed, fertilizer, and labor.

Service capabilities include in-shop repairs and on-farm support through a fleet of service trucks operating 24/7 for emergency repairs. According to internal service data, H&R Agri-Power employs over 100 manufacturer-trained technicians who receive regular training on latest technologies and repair techniques. Planned Maintenance Programs cover routine inspections for combines, tractors, balers, and planters.

The dealership's Planned Maintenance Agreements ensure equipment operates at peak efficiency through scheduled service intervals. Manufacturer warranties combined with promotional financing offers reduce the total cost of ownership by 15-25% compared to standard financing terms. These programs maximize equipment value retention while minimizing unexpected repair costs.

What Are the Key Takeaways About New Holland Attachments Spotlight: Seasonal Tools That Maximize ROI We Covered?

The key takeaways center on strategic selection, proper maintenance, and regional adaptation. Strategic attachment selection requires comparing purchase and operating costs against productivity gains through formal cost-benefit analysis. Net Present Value calculations help determine optimal investment timing.

Proper maintenance protocols include regular lubrication, fluid changes at specified intervals, and wear part replacement according to manufacturer schedules. Compatibility matching between tractors and attachments prevents mechanical failures—T4 Series tractors pair with LA Series loaders based on PTO horsepower, while Boomer™ Compact tractors work with Deluxe and Economy Compact Loaders.

Regional agricultural patterns dictate seasonal tool strategies. Corn Belt operations require different equipment configurations than Southeast farms due to varying crop types, soil conditions, and climate patterns. Storage protocols during off-seasons include cleaning equipment thoroughly, storing in sheltered locations, and lubricating grease points to prevent corrosion.

A holistic approach incorporating maintenance schedules, compatibility verification, and proper storage maximizes equipment lifespan beyond initial purchase. This comprehensive strategy ensures seasonal tools deliver consistent ROI through reduced downtime, lower repair costs, and extended service life.