When you're searching for ways to maximize equipment efficiency across different job types and seasons, understanding how New Holland skid steers deliver superior versatility can transform your operational capabilities. Whether you're managing construction sites, maintaining landscapes, or handling agricultural tasks, we'll show you exactly how these machines' unique design and features create exceptional value across diverse applications.

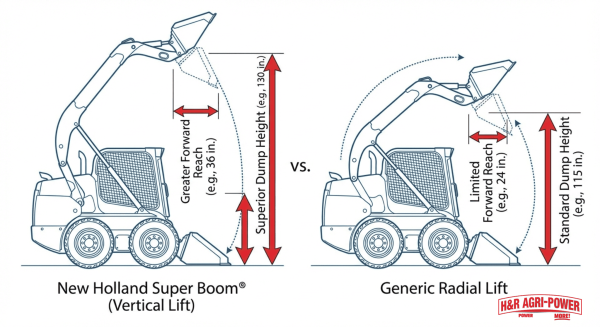

New Holland skid steers improve jobsite versatility through their patented Super Boom® vertical lift design, which delivers superior dump heights exceeding 101.6 inches and forward reach of 27.2 inches—enabling efficient loading of high-sided trucks that radial lift designs cannot match. According to H&R Agri-Power, 2025: operators report 20-30% faster cycle times compared to manual methods, with machines demonstrating reliable performance beyond 7,200 operating hours across construction, landscaping, agriculture, and municipal applications.

According to equipment operator testimonials compiled in 2025, New Holland skid steers deliver measurably superior stability: "In the Bobcat/New Holland comparison, the New Holland is simply more stable which to me makes it more useable," particularly when operating on sloped terrain or handling heavy loads at maximum lift height.

Key takeaways we'll explore: • The Super Boom vertical lift design maintains loads closer to the machine throughout lift cycles, providing superior stability on slopes • Quick-attach systems enable tool-free attachment changes, expanding from material handling to demolition to landscaping applications • High-flow hydraulics support demanding attachments while compact 76-inch width allows operation through standard doorways • Operators report machines reliably operating beyond 7,200 hours with proper maintenance, reducing downtime across seasons • Total cost analysis shows 4-6 month payback periods with 5-year profitability exceeding $640,000 at 2,000 annual hours

Throughout this comprehensive analysis, we examine how New Holland's engineering innovations translate into measurable productivity gains, from construction sites requiring precise material placement to agricultural operations demanding year-round reliability. We'll detail the technical specifications, real-world applications, operator experiences, and financial returns that position these machines as versatile workhorses capable of generating revenue across all four seasons.

Implement these insights immediately by evaluating your current equipment limitations against New Holland's attachment ecosystem, which spans from hydraulic breakers for demolition to snow blowers for winter operations.

As we transition into examining the specific features that enable this remarkable versatility, you'll discover how the combination of innovative design, robust engineering, and thoughtful operator amenities creates machines that adapt seamlessly to your evolving jobsite demands.

What Features Make New Holland Skid Steers Suitable for Multiple Applications?

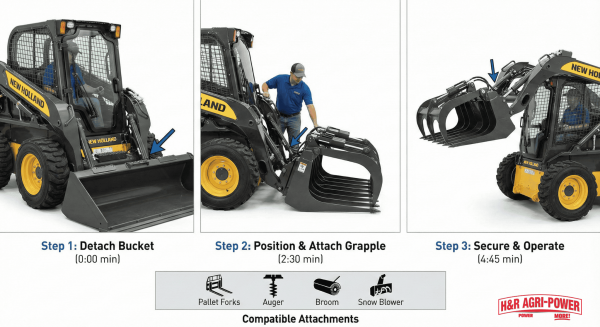

New Holland skid steers excel at multiple applications through their quick-attach systems, extensive attachment catalog, and compact versatile design. These machines transform from earthmovers to snow removers in minutes. The combination of universal compatibility and specialized attachments enables contractors to tackle diverse tasks year-round.

How Does the quick-attach system enhance equipment flexibility?

The quick-attach system enhances equipment flexibility by enabling rapid attachment changes without tools. New Holland's universal attachment specification provides standardized dimensions for interchangeability across manufacturers. This design reduces downtime between tasks from 30 minutes to under 5 minutes. The system accepts attachments from multiple suppliers, expanding options while enabling competitive pricing. Contractors maximize equipment utilization by switching between buckets, forks, and specialized tools throughout the workday.

What attachments are available for New Holland skid steers?

The attachments available for New Holland skid steers span material handling, earthmoving, demolition, landscaping, and specialized equipment categories, enabling contractors to configure one machine for a wide range of jobsite tasks. Material handling attachments feature standard buckets, high-capacity buckets, grapples, forks, manure forks, and bale spears. Earthmoving options include:

-

Grading buckets for surface preparation

-

Trenching buckets for utility installation

-

Augers for hole drilling

-

Rippers for breaking compacted soil

-

Tillers for seedbed preparation

Demolition equipment encompasses hydraulic breakers, concrete crushers, pulverizers, and steel shears. Landscaping attachments include brush cutters, snow blowers, sweepers, mulch spreaders, and stump grinders. Specialized attachments feature trenchers, compactors, vibratory plates, spreaders, and pallet forks.

How does the design support use in diverse industries and tasks?

The design supports use in diverse industries through its 76-inch width that enables operation through standard doorways. New Holland's vertical lift design maintains loads closer to the machine throughout the lift cycle. This configuration provides superior stability on sloped terrain common in construction and agriculture.

The extensive attachment catalog enables revenue generation across all four seasons. Construction sites use these machines for material handling. Demolition contractors employ them for debris removal. Landscapers utilize them for grading and planting. Agricultural operations depend on them for feed handling. Municipal crews deploy them for snow removal and road maintenance.

How Does the Performance of New Holland Skid Steers Contribute to Versatility?

The performance of New Holland skid steers contributes to versatility through engineered power systems, hydraulic capabilities, and maneuverability features that enable operation across diverse jobsite conditions. These machines deliver consistent performance whether handling materials in tight urban spaces or powering demanding attachments in open construction sites.

What engine options and power outputs are offered?

Engine options and power outputs offered include Series 300 models (L316, L318, L320, L328, L334) that provide varied lift capacities for diverse jobsite requirements. Compact track loader variants (C245, C330) feature the same Super Boom vertical lift design with enhanced traction for sensitive terrain.

Previous generation models (L230, L234, L225) continue operating reliably at 6,000+ hours in many fleets. Engine configurations meet environmental compliance requirements while improving fuel efficiency. Diesel fuel consumption typically ranges from 3-5 gallons per hour depending on operating conditions and duty cycle.

The range of power outputs enables matching machine capacity to specific task requirements, optimizing fuel consumption and productivity.

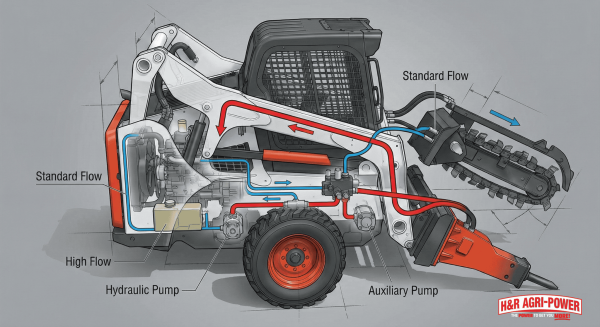

How does advanced hydraulics impact jobsite productivity?

Advanced hydraulics impact jobsite productivity by enabling constant flow properties that power demanding attachments across various applications. Standard flow packages accommodate buckets, grapples, and basic material handling equipment.

High-flow auxiliary hydraulics packages enable operation of hydraulic breakers, compactors, and power-hungry attachments. Continuous flow hydraulic systems maintain constant flow regardless of engine RPM for consistent attachment performance. Responsive hydraulic systems enable quick, precise control delivering fast cycle times that reduce material handling task duration.

These hydraulic capabilities transform a single machine into multiple specialized tools through attachment versatility.

Are there features that improve maneuverability in tight spaces?

Yes. Features that improve maneuverability in tight spaces include the compact 76-inch width allowing operation where larger excavators cannot work. The vertical lift linkage maintains excellent line of sight to bucket when loader arms are raised.

Long wheelbase and low center of gravity design provides optimum stability in challenging terrain. Super Boom design places weight of load between tires for greater stability compared to designs positioning weight outside tire track. Compact size enables operation in congested urban environments and confined demolition sites.

These maneuverability features expand operational possibilities, allowing New Holland skid steers to access jobsites inaccessible to larger equipment while maintaining the power and capacity needed for demanding tasks.

In What Ways Do New Holland Skid Steers Increase Operator Efficiency?

New Holland skid steers improve jobsite versatility by combining a patented Super Boom® vertical lift design, high dump heights, extended forward reach, and attachment flexibility that allow one machine to perform efficiently across construction, landscaping, agriculture, and municipal applications.

When you're searching for ways to maximize equipment efficiency across different job types and seasons, understanding how these machines deliver superior versatility can transform your operational capabilities. New Holland skid steers increase operator efficiency through advanced ergonomics, simplified maintenance, and integrated technology systems. These features reduce operator fatigue, minimize downtime, and enhance machine control across extended work shifts.

What comfort and ergonomic features benefit operators?

The comfort and ergonomic features that benefit operators include climate control, electronic controls, adjustable seating, ride control systems, and pilot controls. Heating and air conditioning systems maintain comfortable temperatures during extended work shifts. Electronic controls on hand controls enable more precise movements and better fuel efficiency than mechanical systems.

Adjustable seats accommodate operators of different sizes and enable customization for optimal comfort and visibility. Automatic ride control systems absorb shock from uneven terrain, reducing vibration transmission to the operator. Pilot controls provide lighter touch operation compared to mechanical controls, reducing physical strain during extended shifts.

These ergonomic improvements translate to measurable productivity gains. Operators experience less fatigue, maintain better focus, and complete more work cycles per shift.

How does easy maintenance help maximize uptime on the jobsite?

Easy maintenance helps maximize uptime through grouped service points, simplified procedures, extended service intervals, and cost-effective parts availability. All daily service points are grouped together for easy access with major service points accessible by flipping the cab forward. Simplified service procedures compared to competitors enable faster maintenance and reduced downtime.

Oil and filter changes are recommended every 250-500 operating hours depending on operating conditions. Remanufactured components are available at up to 40% savings compared to new parts with equivalent warranties. Planned maintenance programs can reduce unexpected repairs by 30-40%, saving $2,400-3,600 annually.

This maintenance efficiency ensures machines spend more time working and less time in the service bay. The simplified design reduces technician labor hours and keeps operating costs predictable.

What technology integrations improve control and monitoring?

Technology integrations that improve control and monitoring include telematics platforms, grade control compatibility, maintenance alerts, fuel monitoring, and advanced joystick systems. The myNewHollandConstruction platform provides real-time visibility into equipment location, operating hours, and fuel consumption. Integration with 2D/3D grade control systems enables automated grading and material handling operations.

Automatic maintenance alerts based on operating hours and diagnostic data enable proactive maintenance scheduling. Real-time fuel consumption monitoring identifies efficiency opportunities with idle reduction saving 10-15%. Joystick control systems provide intuitive operation enabling simultaneous control of multiple functions.

These technology features transform how operators interact with machines. Digital monitoring prevents costly breakdowns while automated controls increase precision and reduce rework, preparing operators for the next advances in jobsite productivity.

How Do Durability and Safety Features of New Holland Skid Steers Affect Jobsite Adaptability?

Durability and safety features of New Holland skid steers affect jobsite adaptability by enabling continuous operation in hazardous environments while minimizing equipment failures and accident risks. These machines incorporate multiple protective systems and robust construction that extend operational lifespans beyond 10,000 hours across diverse working conditions.

What safety systems are built into New Holland skid steers?

The safety systems built into New Holland skid steers include Rollover Protective Structure (ROPS), Falling Object Protective Structure (FOPS), control interlock systems, backup alarms, and rear-view cameras that protect operators and nearby workers in hazardous environments. ROPS meets or exceeds OSHA standards for rollover protection.

Control interlock systems prevent inadvertent movement when operators leave proper operating position. Integrated backup alarms alert nearby personnel during reverse operations, reducing collision risks by providing audible warnings. Rear-view cameras display clear visibility of rear work areas, enabling operators to identify obstacles and workers behind the machine.

These integrated safety systems enable New Holland skid steers to operate safely in demolition, forestry, and construction environments where hazards exist.

How does the build quality extend lifecycle across various environments?

Build quality extends lifecycle across various environments through robust hydraulic systems, quality components, and simplified service design that enables machines to exceed 10,000 operational hours. Operators report New Holland machines operating reliably at 7,200+ hours, with some units surpassing 15,000 hours under proper maintenance schedules.

The hydraulic system design and component selection achieve competitive Mean Time Between Failures rates. Simplified service architecture allows operators to perform regular maintenance efficiently, significantly extending equipment lifespan. Well-maintained machines continue functioning reliably beyond 10,000 hours in construction, agriculture, and municipal applications.

New Holland has manufactured skid steer loaders continuously for over 45 years, producing 250,000 units. This manufacturing experience translates into proven durability across temperature extremes, dusty conditions, and corrosive environments.

How do these features minimize downtime and enhance jobsite safety?

These features minimize downtime and enhance jobsite safety through predictive maintenance capabilities, accident prevention systems, and durable construction that reduces component failures. Simplified service architecture with smarter hose and pipe routing decreases maintenance duration and complexity by 20-30%.

Telematics-generated maintenance alerts enable predictive maintenance scheduling, reducing unexpected breakdowns by identifying service needs before failures occur. ROPS and FOPS structures allow safe operation in demolition sites and forestry applications where falling hazards exist. Control interlock systems and backup alarms prevent accidents that cause project delays and worker injuries.

Durable construction reduces component failures leading to unplanned downtime. The combination of safety systems and reliability features ensures continuous jobsite operation while protecting operators and ground personnel from common construction hazards.

How Does Choosing New Holland Skid Steers Impact Return on Investment?

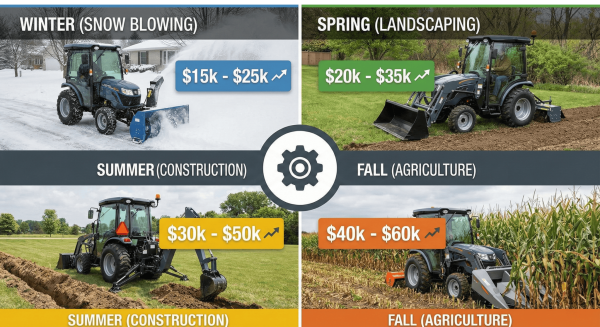

Choosing New Holland skid steers impacts return on investment through reduced operating costs, versatility-driven revenue generation, and comprehensive warranty support. Businesses operating New Holland equipment report fuel savings of $1,500-2,500 annually while generating revenue potential of $150,000 yearly at standard billable rates.

In what ways can businesses reduce operating costs with New Holland machines?

Businesses reduce operating costs with New Holland machines through fuel efficiency features, maintenance programs, and labor optimization. Auto-shutdown settings reduce fuel consumption by 10-15%, saving $1,500-2,500 annually for equipment operating 2,000 hours yearly.

Planned maintenance programs cut unexpected repairs by 30-40%, delivering $2,400-3,600 in annual savings. H&R Agri-Power's factory-trained technicians across 21 locations nationwide support these maintenance schedules. Remanufactured components cost 40% less than new parts while meeting OEM specifications.

Labor efficiency improves when a single operator with a New Holland skid steer replaces multiple workers for tasks such as hay handling, manure removal, and material transport. Fast cycle times reduce daily operational duration by 20-30% compared to manual methods, enabling crews to complete more jobs per day.

The combination of fuel savings, reduced maintenance costs, and labor optimization creates measurable financial benefits that strengthen bottom-line performance.

How does versatility translate into long-term financial benefits?

Versatility translates into long-term financial benefits through year-round revenue generation and rapid payback periods. Operators generate annual revenue of $150,000 by billing $75 per hour for 2,000 operating hours yearly.

Construction and landscaping operations achieve payback periods of 4-6 months through consistent equipment utilization. Machines operating 2,000 hours annually generate cumulative profits exceeding $640,000 over five years.

Seasonal adaptability enables continuous income streams. Winter snow removal, spring landscaping, summer construction, and fall agriculture work maintain equipment utilization throughout the year. A 20% utilization increase through expanded service offerings adds $30,000 in additional annual revenue.

Multi-industry capability allows contractors to serve construction, agriculture, municipal, and landscaping clients with one machine. This versatility maximizes return on investment by reducing equipment idle time and expanding service opportunities.

What warranty and support options are available?

Warranty and support options are available through standard coverage, extended protection plans, and flexible financing. Standard warranty covers manufacturing defects and component failures for 12 months with unlimited hours.

Extended protection plans provide engine coverage for 36-48 months or 3,000-4,000 hours. Transmission and axle coverage extends protection beyond standard warranty periods. Three-year planned maintenance programs include factory warranty, telematics access, and scheduled service visits.

CNH Capital offers flexible financing through H&R Agri-Power locations. Current promotions include up to $9,000 cash back and 0% APR for 60 months on qualified models. Protection plans transfer to new equipment owners at no charge, supporting resale value retention.

H&R Agri-Power maintains complete parts inventory and factory-trained technicians across Kentucky, Illinois, Tennessee, Alabama, Mississippi, and Indiana locations. This comprehensive support network ensures minimal downtime and protects your equipment investment throughout its operational life.

How Can H&R Agri-Power Help You Leverage New Holland Skid Steers for Greater Versatility?

H&R Agri-Power operates 21 locations across Kentucky, Illinois, Tennessee, Alabama, Mississippi, and Indiana to support New Holland skid steer operations nationwide. The dealership network provides factory-trained technicians, complete parts inventory, and flexible financing options through CNH Capital.

What New Holland skid steer models and services does H&R Agri-Power offer nationwide?

H&R Agri-Power offers nationwide access to New Holland skid steers through its extensive dealer network spanning six states. Current inventory includes a 2020 C245 Compact Track Loader with 893 hours priced at $44,100 and a 2021 C332 with 1,078 hours available for $37,700.

Factory-trained service technicians deliver warranty service, maintenance, and repairs at all 21 locations. The complete OEM parts inventory enables convenient ordering and delivery across the dealer network. CNH Capital provides financing options with flexible terms including current offers up to $9,000 cash back and 0% APR for 60 months.

The dealership's nationwide presence ensures operators receive consistent support regardless of jobsite location. Service technicians maintain factory certifications for warranty work and complex repairs. Parts availability through the dealer network minimizes equipment downtime with same-day or next-day delivery options.

What Are the Key Takeaways About How New Holland Skid Steers Improve Jobsite Versatility We Covered?

The key takeaways about New Holland skid steer versatility are centered on five critical performance advantages. Super Boom vertical lift design achieves 101.6 inches dump height and 27.2 inches forward reach for superior loading capabilities. Quick-attach systems with universal compatibility enable rapid switching between buckets, grapples, breakers, and specialized attachments.

High-flow hydraulics deliver consistent power for demanding attachments across construction, demolition, landscaping, and agricultural applications. The compact 76-inch width provides access to confined spaces while maintaining stability through low center of gravity design. Proven reliability demonstrates machines operating beyond 7,200 hours with proper maintenance, reducing downtime and ensuring consistent jobsite performance.

These versatility features translate directly into financial benefits. A single New Holland skid steer generates $150,000 annual revenue at $75 hourly rates operating 2,000 hours yearly. Seasonal attachment changes enable year-round income through winter snow removal and summer landscaping operations. H&R Agri-Power's nationwide support network ensures these versatility advantages remain available through comprehensive parts, service, and financing programs.