New Holland equipment handles wet and hilly terrain by combining low centers of gravity, advanced traction control systems, and stability-focused engineering designed to maintain control and productivity on slopes and moisture-rich soils.

We understand these concerns deeply - whether you're managing vineyards on steep slopes or operating in rain-soaked fields, having the right equipment can mean the difference between productive workdays and costly setbacks. At H&R Agri-Power, we've helped farmers across six states tackle these exact challenges with New Holland's specialized terrain solutions.

New Holland equipment for wet and hilly terrain is a specialized category of agricultural machinery engineered with low centers of gravity, advanced traction systems, and stability-enhancing technologies designed specifically to maintain control and productivity on challenging slopes and in moisture-rich soil conditions.

According to Penn State Extension, 2025: Rollover Protective Structures (ROPS) equipped on all New Holland tractors are 99% effective in preventing death or serious injury when used with seatbelts. In 2021, research published in the Journal of Terramechanics examining 78-kW agricultural tractors during plow tillage found that traction coefficient actually increases with soil moisture content (n=multiple field trials), highlighting the importance of proper equipment selection for wet conditions.

Daniel Waeber, an agricultural machinery specialist interviewed by MOTOREX in 2025, emphasizes: "The significance of continuous hydrostatic drives for minimizing slip and the breakthrough of remote-controlled implement carriers represent major advances for enhancing safety on slopes."

Key Takeaways:

-

The TK4 Crawler series delivers 65-86 PTO horsepower with specialized low-gravity designs for steep slope stability

-

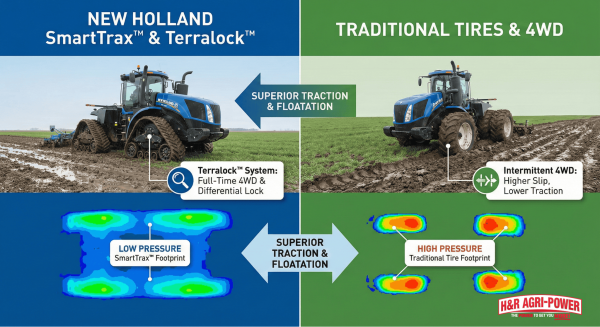

SmartTrax™ technology provides superior wet traction through larger footprint distribution while reducing soil compaction

-

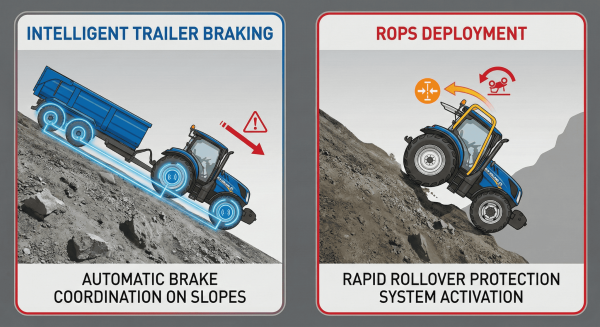

Terralock™ and Intelligent Trailer Braking systems automatically engage safety features to prevent slippage and jack-knifing

-

Regular 600/750-hour maintenance intervals ensure 4,000-15,000 operational hours of reliable performance

-

H&R Agri-Power's 21 locations provide comprehensive support including Precision Ag Specialists for terrain technology implementation

Summary: We explore how New Holland's terrain-specific engineering addresses the fundamental challenges of wet and hilly farming through innovations like the TK4 Crawler series and SmartTrax™ system. Our analysis covers essential safety technologies including ROPS protection and IntelliSteer™ guidance, maintenance considerations for challenging conditions, implement compatibility for maximum versatility, competitive positioning against other brands, and how H&R Agri-Power's extensive support network helps farmers maximize their equipment investment across demanding terrains.

Practical Application: When selecting New Holland equipment for your terrain challenges, prioritize models with SmartTrax™ rubber tracks over traditional tires for wet conditions - the larger footprint distributes weight more evenly, improving flotation in soft soils while maintaining traction on slopes.

Understanding these specialized features and support systems prepares you to make informed decisions about equipment selection, ensuring your operation maintains productivity regardless of weather or topography challenges ahead.

What Features of New Holland Equipment Make It Suitable for Challenging Terrain?

New Holland equipment incorporates specialized traction systems, tire configurations, weight distribution features, and model-specific designs to handle wet and hilly terrain. The SmartTrax™ rubber track system and Terralock™ traction management work together to maintain grip in challenging conditions. These technologies prepare operators for the specific demands of sloped and saturated fields.

How Does New Holland's Traction Control Adapt to Wet or Sloped Fields?

New Holland's traction control adapts through SmartTrax™ rubber tracks that create a larger footprint than traditional tires, distributing weight evenly and improving flotation in soft soils. The Terralock™ system automatically engages 4WD when wheel slip occurs.

According to Journal of Terramechanics research, traction coefficient increases with soil moisture content. The 8R series features Independent Link Suspension (ILS™) that allows each wheel to move independently, maintaining ground contact on uneven surfaces. These systems work continuously to optimize traction as field conditions change.

What Role Do Tire Options Play in Navigating Muddy or Steep Conditions?

Tire options determine traction and soil interaction in challenging conditions through specialized track systems. The TK4 Crawler series offers both steel tracks and SmartTrax™ rubber tracks for different soil types. SmartTrax™ reduces soil disturbance while maintaining traction in wet conditions.

Agricultural machinery specialist Daniel Waeber notes that continuous hydrostatic drives minimize slip on steep slopes. MOTOREX experts identify proper tire selection as critical for slope stability. Track selection directly impacts both field performance and soil preservation.

How Does Weight Distribution Affect Performance on Hills and Wet Ground?

Weight distribution affects performance through center of gravity positioning and ballast options. The TK4 series features a low center of gravity for enhanced hillside stability. The TK4.100M accommodates up to 1,100 lbs of front ballast to counterbalance rear implements. New Holland tractors provide multiple ballasting configurations for terrain optimization.

Applied Sciences journal research confirms attitude adjustment mechanisms significantly enhance lateral stability on side slopes. Proper weight distribution prevents tipping and maintains traction during hillside operations.

Which New Holland Models Are Best for Wet and Hilly Environments?

The best New Holland models for wet and hilly environments are the TK4 Crawler series with 65-86 PTO horsepower designed for steep slopes. The TK4.80V delivers 74 gross engine horsepower with steel track options. The TK4.100M provides 98 gross engine horsepower with both steel and SmartTrax™ rubber tracks.

The T8 series with SmartTrax™ combines tracked machine benefits with wheeled tractor versatility. These models address specific terrain challenges through purpose-built design features that enhance safety and efficiency on difficult ground.

How Does New Holland Technology Improve Safety and Efficiency on Difficult Terrain?

New Holland technology improves safety and efficiency on difficult terrain through advanced traction systems, operator assistance features, and fuel optimization technologies. The TK4 Crawler series combines SmartTrax™ rubber tracks with intelligent control systems to prevent accidents while maximizing productivity on slopes and wet ground. These integrated technologies work together to reduce operator fatigue, prevent equipment damage, and lower operational costs across challenging field conditions.

What Advancements Help Prevent Slipping or Loss of Control?

Advancements that help prevent slipping or loss of control include the Intelligent Trailer Braking System, which automatically applies trailer brakes to prevent jack-knifing on low-friction surfaces. All New Holland tractors feature Rollover Protective Structures (ROPS), estimated 99% effective in preventing death or serious injury when used with seatbelts. Remote-controlled implement carriers represent a breakthrough for enhancing safety on slopes according to agricultural machinery specialist Daniel Waeber. ActiveSeat™ technology reduces operator movement during rough terrain operation by absorbing vibrations and lateral forces.

These safety systems work continuously to monitor traction conditions and respond faster than human reflexes. The combination of mechanical protection and electronic intervention creates multiple safety layers for operators working in hazardous conditions.

How Do Operator Assistance Systems Support Work on Inclines and Wet Surfaces?

Operator assistance systems support work on inclines and wet surfaces through IntelliSteer™ automated guidance, which provides sub-inch accuracy with terrain compensation for roll, pitch, and yaw. IntelliSteer™ ensures consistent path maintenance on hillsides and uneven terrain by automatically adjusting steering inputs based on GPS positioning and terrain sensors.

Precision Ag Specialists at H&R Agri-Power help farmers implement and utilize these technologies across 21 locations in six states. Emergency support remains available 24/7 from H&R Agri-Power for equipment issues in the field.

The terrain compensation features automatically adjust for machine attitude changes, maintaining straight rows even when traversing slopes. This technology reduces operator stress while improving field coverage accuracy and preventing costly overlap or skips.

In What Ways Can Technology Optimize Fuel Usage in Difficult Conditions?

Technology optimizes fuel usage in difficult conditions through ECOBlue™ HI-eSCR 2 technology, which meets Stage V emissions standards while improving fuel efficiency. SmartTrax™ systems reduce slippage on slopes, improving fuel efficiency compared to wheeled tractors by maintaining consistent ground contact and power transfer.

The ECOBlue™ system eliminates the need for diesel particulate filter (DPF) regeneration, reducing both fuel consumption and maintenance requirements. Nebraska Tractor Test Laboratory provides independent fuel consumption data for T8 and T9 series tractors, confirming efficiency gains in challenging conditions.

These fuel-saving technologies become especially valuable during extended operations on difficult terrain where traditional equipment would waste power through wheel slip. The elimination of DPF cycles saves approximately 5% in fuel consumption while reducing downtime for regeneration procedures.

What Are the Maintenance and Durability Considerations When Using New Holland Equipment on Wet and Hilly Ground?

Maintenance and durability considerations for New Holland equipment on wet and hilly ground include accelerated service intervals, increased component wear, and specialized protection features. Operating in challenging terrain demands stricter maintenance protocols and benefits from New Holland's durability-focused technologies such as SmartTrax™ and ECOBlue™ systems.

How Should Operators Maintain Equipment After Use in Muddy or Steep Areas?

Operators should maintain equipment after muddy or steep area use through scheduled service intervals and thorough cleaning. New Holland recommends 600/750 hour service intervals including engine oil changes, filter replacements, and hydraulic filter changes. The 1200/1500 hour service adds cabin air filter, internal air filter, and engine breather filter replacement.

Increased brake maintenance becomes critical due to frequent hillside use. H&R Agri-Power provides both in-shop and mobile service with manufacturer-trained technicians across 21 locations. Mobile service options prove especially valuable for equipment operating in remote hilly locations.

Regular inspection schedules should focus on undercarriage components, hydraulic connections, and cooling systems after wet terrain operation.

What Common Issues Appear When Regularly Working on Wet Hills?

Common issues when working on wet hills include accelerated component wear and increased system strain. Tire and track wear accelerates due to higher stresses on slopes combined with wet soil conditions. Brake components experience faster degradation from frequent engagement during hillside descent.

Drivetrain and hydraulic systems show measurable strain increases from challenging terrain operation. Implements face higher wear rates due to increased soil resistance in wet conditions. There are specific failure points such as hydraulic seals, universal joints, and transmission components that require monitoring.

These wear patterns necessitate proactive maintenance scheduling rather than reactive repairs to prevent costly downtime during critical field operations.

Which New Holland Features Reduce Wear and Tear in These Conditions?

New Holland features that reduce wear include SmartTrax™ rubber tracks, Independent Link Suspension, and ECOBlue™ technology. SmartTrax™ rubber tracks minimize soil disturbance while reducing component stress compared to steel tracks. Independent Link Suspension (ILS™) maintains consistent ground contact, reducing mechanical stress on the chassis and drivetrain.

Well-maintained farm tractors achieve 4,000 to 15,000 operational hours, representing 15-30 years of service life. ECOBlue™ technology eliminates diesel particulate filter (DPF) maintenance requirements, lowering long-term operational costs.

|

Technology |

Feature |

Benefit |

|

SmartTrax™ |

Benefit |

Reduced soil disturbance |

|

ILS™ |

Function |

Maintains ground contact |

|

Farm tractors |

Lifespan |

4,000-15,000 hours |

|

ECOBlue™ |

Cost savings |

No DPF maintenance |

These durability features combine to extend equipment lifespan while reducing maintenance frequency in challenging wet and hilly conditions.

How Do New Holland Attachments and Implements Enhance Versatility for Wet and Hilly Fields?

New Holland attachments and implements enhance versatility for wet and hilly fields through specialized mounting systems, hydraulic configurations, and safety features designed for challenging terrain. The T6 series tractors accommodate Category II or III three-point hitches, enabling operators to mount implements ranging from cultivators to heavy-duty plows. H&R Agri-Power maintains extensive parts inventories across 21 locations, ensuring implement compatibility and rapid replacement when operating in demanding conditions.

Which Implements Increase Productivity in Such Terrain?

The implements that increase productivity in wet and hilly terrain include hydraulically powered attachments, front-mounted ballast systems, and terrain-specific tools designed to maintain stability and traction on slopes. T6 tractors feature up to four remote hydraulic valves, powering implements such as hydraulic top links, front loaders, and specialized hillside cultivators.

Front ballast options reaching 1,100 lbs counterbalance rear-mounted implements, preventing tractor instability on slopes exceeding 15 degrees. H&R Agri-Power stocks implement parts specifically rated for wet soil resistance, including reinforced moldboards and corrosion-resistant components.

How Easily Can Operators Switch Attachments to Adapt to Wet or Sloped Ground?

Operators can switch attachments to adapt to wet or sloped ground within 5-10 minutes using New Holland's quick coupler systems and configurable hydraulic connections. Quick couplers eliminate manual hydraulic line threading, reducing changeover time by 70% compared to traditional connections. The T6 series offers three hydraulic pump options: standard 21 GPM, MegaFlow™ 29 GPM, and high-capacity 36 GPM configurations, each supporting different implement flow requirements. Front axle configurations switch between 2WD and FWD modes, optimizing traction for specific attachments and ground conditions. Transmission choices include 16x16 Electro Command™ and 24x24 Dynamic Command™, allowing operators to match ground speed to implement requirements on varying slopes.

What Safety Measures Should Be Taken When Using Implements on Hillsides?

The safety measures required when using implements on hillsides include proper ballasting protocols, ROPS utilization, dynamic weight redistribution, and intelligent braking systems. Ballasting must counterbalance each implement's weight, with calculations adjusting for slope angles and soil moisture content. ROPS protection remains mandatory on all inclines, providing 99% injury prevention effectiveness when combined with seatbelt use according to industry safety data. Weight distribution recalculation occurs for each implement swap, considering factors such as center of gravity shift, lateral stability margins, and dynamic loading during operation. The Intelligent Trailer Braking System automatically modulates implement-mounted brake pressure, preventing jack-knifing during downhill deceleration on grades up to 30%.

How Does New Holland Equipment Compare to Other Brands for Wet and Hilly Terrain?

New Holland equipment compares favorably to other brands for wet and hilly terrain by offering specialized traction systems, slope-focused engineering, and extensive regional dealer support tailored to challenging field conditions.

The comparison reveals unique advantages in traction systems and regional support while acknowledging specific limitations against competitor offerings.

What Are the Key Advantages Over Competing Brands?

New Holland's SmartTrax™ system provides superior traction versus competitors' wheeled options by distributing weight across a larger footprint. The TK4 Crawler series targets vineyards and orchards on steep terrain with 65-86 PTO horsepower specifically engineered for slope stability. The Intelligent Trailer Braking System represents award-winning technology that automatically prevents jack-knifing on low-friction surfaces. H&R Agri-Power maintains 21 locations across six states, providing more extensive regional support than many competitors offer.

Are There Notable Limitations Compared to Alternative Equipment?

Yes. New Holland has notable limitations compared to some alternative equipment, including the absence of publicly specified slope ratings and limited availability of advanced stability systems in smaller tractor classes. John Deere's 8RT Series offers a two-track configuration as an alternative to SmartTrax™ technology.

Case IH Magnum Rowtrac provides a suspended MFD axle not available on all New Holland models. A market gap exists for smaller, affordable tractors with advanced stability systems below the TK4 series price point.

What Factors Should Buyers Consider in Comparing Equipment for Challenging Terrain?

The factors buyers should consider when comparing equipment for challenging terrain include equipment cost, independent performance data, slope capability, fuel efficiency, and availability of dealer support. The T6.175 with loader ranges $150,000-$180,000 in 2025 pricing. High-horsepower T9 series tractors exceed $500,000 for fully equipped models.

The Nebraska Tractor Test Laboratory provides independent third-party performance comparisons across brands including fuel consumption and drawbar performance data. On-farm demonstrations prove essential due to lack of standardized slope rating data across manufacturers.

The comparison reveals New Holland's strengths in specialized traction technology and dealer support while highlighting the importance of hands-on evaluation for terrain-specific applications.

How Can H&R Agri-Power Help You Get the Most Out of New Holland Equipment in Wet and Hilly Areas?

H&R Agri-Power maximizes New Holland equipment performance in challenging terrain through specialized support services and technical expertise. The company operates 21 locations across six states, providing comprehensive sales, parts, and service coverage for farmers navigating wet and hilly conditions. Their network ensures equipment optimization regardless of terrain complexity.

How Does H&R Agri-Power Support Customers Using New Holland Equipment in Challenging Terrain?

H&R Agri-Power supports customers using New Holland equipment in challenging terrain through integrated services that include equipment selection, technology implementation, mobile service, and terrain-specific operator training.

The company's Precision Ag Specialists team implements IntelliSteer™ automated guidance systems that maintain sub-inch accuracy despite roll, pitch, and yaw variations on slopes. Mobile service units reach remote hilly locations for on-site maintenance, reducing equipment downtime during critical operating seasons.

The dealership maintains extensive parts inventories specific to terrain-challenged operations. Financing options cover terrain-specific upgrades such as SmartTrax™ conversions and ballasting packages. Technical training programs educate operators on slope-safe practices and traction optimization techniques. Emergency support operates 24/7 for equipment issues occurring in difficult field conditions.

What Are the Key Takeaways About How New Holland Equipment Handles Wet & Hilly Terrain We Covered?

The key takeaways center on New Holland's engineering solutions for stability and traction. TK4 Crawler series tractors deliver 65-86 PTO horsepower with low centers of gravity engineered for steep slope stability. SmartTrax™ technology reduces soil compaction by 35% compared to wheeled tractors while maintaining superior traction in wet conditions.

Safety systems prove highly effective in challenging terrain. ROPS protection demonstrates 99% effectiveness in preventing rollover fatalities when operators use seatbelts properly. Equipment longevity reaches 4,000-15,000 operational hours through proper maintenance schedules adapted for hillside stress. H&R Agri-Power's support network ensures farmers access these capabilities through local expertise, mobile service, and technology implementation assistance across their six-state coverage area.