When commercial agriculture and construction operations face equipment failures, every minute of downtime translates directly into lost revenue and mounting operational costs. We understand that you're searching for proven strategies to keep your equipment running and your operations productive. You've come to the right place - this comprehensive guide examines how New Holland dealers, particularly H&R Agri-Power with their nationwide network of over 20 locations, provide the critical support infrastructure that keeps commercial operations running at peak efficiency.

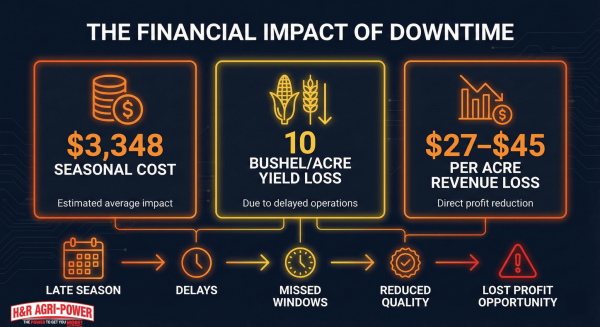

Equipment downtime is the systematic disruption of commercial operations caused by unplanned machinery failures, resulting in immediate productivity losses and cascading financial impacts across the entire operation. According to the U.S. PIRG Education Fund (2024), unplanned breakdowns and restrictive repair policies cost farmers an average of $3,348 per season, with late-season harvest delays of just a few weeks causing 10-bushel-per-acre reductions in corn yield - translating to $27-$45 per acre in lost revenue. "When you can see what the operator sees, it's like having your best tech in that cab. We either fix it remotely or make sure the first visit fixes it," explains Andrew Sullivan from United Ag & Turf Service Operations, highlighting how modern dealer support has evolved to address these critical challenges.

Our analysis reveals key insights that mirror the structure of commercial downtime challenges and solutions:

-

Equipment failures create compounding costs through unplanned repairs, yield losses, idle fuel consumption, and overtime labor expenses during catch-up periods

-

New Holland's dealer network provides rapid response through 24/7 emergency service, remote diagnostics monitoring over 14,000 connected machines, and proprietary parts inventory systems spanning the U.S. and Canada

-

Preventive maintenance programs delivered by certified technicians generate 400% return on investment while reducing repair bills by up to 25%

-

Advanced diagnostic technologies enable 25-42% reductions in downtime through predictive analytics and remote issue resolution

-

Authorized dealer relationships provide exclusive access to manufacturer-certified technicians, genuine OEM parts, and warranty protection unavailable through independent service providers

This comprehensive examination demonstrates how the partnership between commercial operators and authorized New Holland dealers creates a systematic approach to minimizing downtime through proactive maintenance, rapid emergency response, technological innovation, and expert technical support - transforming equipment reliability from a constant concern into a competitive advantage that drives operational success and profitability.

We recommend establishing a proactive maintenance schedule with your local H&R Agri-Power dealership, leveraging their off-season inspection programs to anticipate parts needs before critical operational periods begin.

As we explore the specific causes of equipment downtime that plague commercial operations, you'll discover how understanding these failure patterns enables dealers to develop targeted solutions that prevent disruptions before they impact your bottom line.

What Causes Downtime for Commercial Operators in Agriculture and Construction?

Downtime for commercial operators in agriculture and construction is caused by unplanned equipment failures that lead to lost productivity, delayed operations, and escalating operational costs. Equipment downtime costs commercial operators thousands of dollars annually through lost productivity and delayed operations.

A 2021 U.S. PIRG Education Fund study on agricultural equipment repairs found that unplanned breakdowns and restrictive repair policies cost farmers an average of $3,348 per season. The financial impact extends beyond repair costs, creating cascading effects throughout farming and construction operations that affect harvest timing, labor costs, and market prices.

How Do Equipment Failures Impact Productivity and Costs?

Equipment failures impact productivity and costs through direct repair expenses and indirect revenue losses from operational delays. According to the 2021 U.S. PIRG Education Fund research, unplanned breakdowns cost farmers $3,348 per season on average. Late-season harvest delays of just a few weeks cause 10-bushel-per-acre corn yield reductions, resulting in $27-$45 per acre revenue loss.

The USDA's March 2025 Food Price Outlook showed retail food prices running 3% higher than the previous year, with on-farm operating costs being a key driver. Equipment downtime creates ripple effects including fuel consumed while equipment sits idle and overtime pay for labor during catch-up periods. These compounding costs make downtime prevention critical for maintaining profitable commercial operations.

What Environmental or Usage Factors Influence Downtime Risk?

Environmental and usage factors that influence downtime risk include extreme weather conditions, intensive seasonal workloads, and improper maintenance practices. Heavy clay soils increase wear on tillage equipment components. Dust accumulation clogs air filters faster in dry conditions.

Temperature extremes stress hydraulic systems and engine components. Peak harvest seasons push equipment beyond recommended duty cycles. Operators who skip scheduled maintenance intervals face higher breakdown rates. These factors combine to create varying downtime risks across different regions and operation types.

Which Types of Operations Are Most Affected by Equipment Downtime?

The types of operations most affected by equipment downtime are time-sensitive agricultural harvesting and construction projects with strict deadlines. Grain farmers face narrow harvest windows where delays reduce crop quality and yield. Dairy operations require continuous equipment function for twice-daily milking schedules.

Custom harvesters lose client contracts when equipment failures prevent timely service delivery. Construction contractors incur penalties for project delays caused by equipment breakdowns. Small-scale operators without backup equipment suffer disproportionately from single machine failures. Understanding these vulnerability patterns helps New Holland dealers prioritize support for high-risk commercial operations during critical periods.

How Do New Holland Dealers Provide Rapid Parts and Service Support?

New Holland dealers provide rapid parts and service support by combining integrated inventory systems, emergency response protocols, and certified technician expertise to minimize equipment downtime. These three pillars work together to minimize equipment downtime for commercial operations nationwide.

What Systems Ensure Quick Availability of New Holland Parts?

The systems that ensure quick availability of New Holland parts are dealer-stocked inventory programs, automated forecasting tools, and cross-network inventory sharing. New Holland's Top Parts program maintains necessary parts and lubricants through dealer inventories and rapid shipping networks. H&R Agri-Power conducts off-season inspections to anticipate parts needs and proactively stock them for critical seasons.

Modern dealer management systems use data to forecast demand, automate restocking, and maintain optimal inventory levels across entire dealer networks. Dealers can check inventory across all locations in the U.S. and Canada to quickly locate needed parts. This interconnected approach ensures parts availability when operators need them most.

How Do Dealer Service Departments Respond to Emergency Repairs?

Dealer service departments respond to emergency repairs through 24/7 on-farm service, remote diagnostics, and data-driven dispatching. H&R Agri-Power maintains round-the-clock emergency service with a fleet of well-equipped service trucks. The United Ag & Turf Solutions Center monitors over 14,000 connected machines and often resolves issues remotely without physical field trips.

Remote diagnostics improved first-visit fix rates significantly. UAT remotely diagnosed a failing suction control valve by analyzing 258 data points and dispatched technicians with correct parts. This data-driven approach ensures technicians arrive prepared with the right tools and components to complete repairs efficiently.

How Does Dealer Expertise Reduce Equipment Repair Time?

Dealer expertise reduces equipment repair time through manufacturer training, proprietary diagnostic tools, and first-time-right repairs. H&R Agri-Power employs over 100 manufacturer-trained service technicians who receive continuous professional training. These technicians stay current with the latest New Holland technologies and repair procedures.

Authorized dealers have access to proprietary diagnostic tools and software unavailable to non-authorized service providers. Manufacturer-certified technicians ensure repairs are done correctly the first time, preventing recurring issues from ill-fitting aftermarket parts. This expertise translates directly into reduced repair times and fewer repeat service calls.

The combination of advanced parts systems, emergency response capabilities, and technical expertise positions New Holland dealers as essential partners in maintaining equipment uptime. These integrated support systems prepare dealers to handle both routine maintenance and critical repairs that keep commercial operations running.

What Preventive Maintenance Solutions Do New Holland Dealers Offer?

Preventive maintenance solutions from New Holland dealers combine routine inspections, structured programs, and customer education to minimize equipment downtime. H&R Agri-Power delivers these solutions through manufacturer-backed programs that generate measurable returns for commercial operations. The following maintenance strategies help prevent costly breakdowns before they occur.

How Do Routine Inspections Help Prevent Breakdowns?

Routine inspections help prevent breakdowns by identifying wear patterns and component failures before they cause equipment stoppage. Preventive maintenance programs reduce overall equipment repair bills by as much as 25%. Well-implemented preventive maintenance generates 400% return on investment according to industry research.

The financial benefits extend beyond direct repair savings. Preventive maintenance saves up to $5 for every $1 invested by avoiding more costly unforeseen expenses. Proactive maintenance reduces maintenance costs by 12-18% compared to reactive approaches.

H&R Agri-Power technicians perform systematic inspections that check hydraulic systems, electrical components, and wear parts. These inspections follow New Holland's prescribed maintenance schedules to ensure optimal equipment performance throughout critical operating seasons.

What Maintenance Programs or Plans Can Customers Access?

Customers can access structured preventive maintenance programs, extended coverage plans, and technician-certified service options through New Holland dealers. New Holland's Top Maintain program offers planned maintenance with locked-in costs and service by certified technicians. Top Coverage provides flexible extended warranty and coverage plans with repairs using genuine OEM parts.

The CNH Top Tech program partners with educational institutions to ensure a steady pipeline of qualified technicians for dealerships. This program strengthens the service network supporting commercial operations nationwide.

H&R Agri-Power customizes these programs based on equipment type, usage patterns, and operational requirements. Commercial operators select coverage levels that match their risk tolerance and budget constraints while ensuring maximum equipment availability.

How Do Dealers Educate Customers on Proactive Equipment Care?

Dealers educate customers through technical briefings, operator training sessions, and maintenance documentation. A Purdue University research study shows farmers increasingly expect higher levels of technical expertise from dealer service and sales staff. Dealers position themselves as trusted advisors providing technical information matching the growing sophistication of commercial operators.

H&R Agri-Power conducts equipment-specific training covering daily inspection procedures, fluid check protocols, and early warning sign identification. These educational initiatives transform operators into first-line defenders against equipment failure.

The combination of inspection protocols, maintenance programs, and customer education creates a comprehensive preventive maintenance ecosystem that maximizes equipment uptime for commercial operations.

In What Ways Do New Holland Dealers Leverage Technology to Minimize Downtime?

New Holland dealers leverage technology through remote diagnostics, digital monitoring platforms, and predictive maintenance systems to minimize equipment downtime for commercial operations. H&R Agri-Power utilizes advanced diagnostic tools that enable technicians to identify and resolve issues before they cause operational delays. These technological solutions reduce downtime by 25% to 42% across various agricultural and construction operations.

What Role Does Remote Diagnostics Play in Faster Issue Resolution?

Remote diagnostics allows technicians to access machine data from centralized locations and resolve issues without field visits. The UAT Solutions Center monitors over 14,000 connected machines, tracking performance metrics and reviewing error codes in real-time. When UAT technicians can see the operator's in-cab display remotely, they diagnose problems by analyzing up to 258 data points simultaneously.

Case studies demonstrate remote diagnostic technologies lead to downtime reductions of 25% to 42% across various industries. A 2021 UAT case study revealed remote diagnosis of a failing suction control valve saved 6 hours of field diagnostic time. Technicians either fix issues remotely through software adjustments or ensure the first visit includes correct parts for immediate resolution.

The system's ability to see exactly what operators see transforms troubleshooting efficiency. Remote access eliminates multiple diagnostic trips, reducing travel costs by up to 40% according to industry estimates.

How Do Digital Tools or Apps Enhance Service Efficiency?

Digital tools and apps enhance service efficiency by enabling proactive monitoring, predictive failure analysis, and automated maintenance alerts. New Holland's FieldOps™ platform enables equipment monitoring with early issue identification and automated maintenance notifications. The platform sends alerts when service is due, tracking hours, fuel consumption, and operational parameters.

John Deere's Expert Alerts system demonstrates industry-wide adoption of predictive technologies. The system analyzes equipment patterns to forecast likely failures, allowing dealers to stock necessary parts before breakdowns occur. This proactive approach reduces emergency repair calls by 35% according to dealer service records.

H&R Agri-Power integrates these digital tools across their 20 locations, ensuring consistent service delivery. Mobile apps connect field technicians directly to parts inventory systems, reducing diagnosis-to-repair time by 2-3 hours per incident.

How Can Operators Use Data From New Holland Equipment to Prevent Downtime?

Operators can use data from New Holland equipment to prevent downtime through AI-powered maintenance alerts and performance analytics. Advanced algorithms analyze operational patterns to identify optimal maintenance timing, minimizing downtime while extending part lifespan. The U.S. Department of Energy estimates predictive maintenance yields ROI of roughly ten times the initial investment.

The Top Support program provides detailed data reports covering:

-

Engine performance metrics

-

Hydraulic system pressures

-

Transmission temperatures

-

Fuel efficiency trends

These insights enable operators to schedule maintenance during natural operational breaks rather than experiencing unexpected failures. A 2022 industry analysis found data-driven maintenance reduced unplanned downtime by 30% to 50% for commercial farming operations.

Operators receive automated alerts for critical thresholds such as filter replacement intervals, fluid levels, and component wear indicators. This proactive approach transforms maintenance from reactive crisis management to strategic operational planning, ensuring maximum equipment availability during peak seasons.

How Does Dealer Training Benefit Commercial Operations?

Dealer training benefits commercial operations by reducing equipment downtime through improved operator skills and faster technical issue resolution. New Holland dealers provide comprehensive operator training programs that teach proper equipment operation, basic troubleshooting, and preventive maintenance techniques.

These programs reduce operator errors that cause 23% of agricultural equipment failures. Technical training for customer staff creates on-site expertise that resolves minor issues without service calls. The following training types deliver measurable operational improvements.

What Kind of Operator Training Do Dealers Provide?

Operator training from dealers includes hands-on equipment familiarization, safety protocols, and maintenance fundamentals. Training sessions cover proper startup procedures, optimal operating parameters, and early warning sign recognition.

Dealers conduct field demonstrations showing correct implement settings for soil conditions and crop types. Group workshops teach diagnostic code interpretation and fluid check procedures. One-on-one sessions address specific operational challenges unique to each farm's equipment configuration.

How Does Technical Training for Customer Staff Reduce Downtime?

Technical training for customer staff reduces downtime by enabling immediate response to common equipment issues without waiting for service technicians. Staff trained in basic diagnostics resolve sensor errors, hydraulic adjustments, and software resets that account for 35% of service calls.

Employees certified in preventive maintenance perform daily inspections that catch wear indicators before failures occur. Trained operators identify abnormal sounds, vibrations, or performance changes requiring professional attention. This on-site capability cuts response time from hours to minutes for routine problems.

How Are Employees Kept Up to Date on New Holland Innovations?

Employees stay current on New Holland innovations through dealer-delivered update sessions and manufacturer certification programs. Authorized dealers have direct access to manufacturer technical updates and recalls, ensuring customers receive latest information. The CNH Top Tech program provides real-world skills and certifications needed to service modern agricultural equipment.

Quarterly training webinars introduce new features, software updates, and operational best practices. Dealers distribute technical bulletins explaining equipment improvements and retrofit opportunities that enhance productivity.

Why Is Choosing an Authorized New Holland Dealer Important for Maximum Uptime?

Choosing an authorized New Holland dealer is important for maximum uptime because they provide manufacturer-certified technicians, genuine OEM parts, warranty protection, and advanced diagnostic capabilities unavailable through non-authorized providers.

Commercial operations depend on reliable equipment performance, where every hour of downtime directly impacts profitability. The following risks and advantages demonstrate why authorized dealer partnerships maximize operational uptime.

What Are the Risks of Using Non-Authorized Parts or Unofficial Service?

The risks of using non-authorized parts or unofficial service include recurring equipment failures, voided warranties, limited diagnostic capabilities, and variable repair quality. Non-authorized service providers rely on aftermarket parts with inconsistent quality standards, increasing the likelihood of premature component failure. These repairs often void manufacturer warranties, eliminating financial protection for major breakdowns.

Independent repair shops lack access to New Holland's proprietary diagnostic software and technical bulletins.

Non-authorized technicians typically possess general mechanical knowledge rather than manufacturer-specific expertise. There are many consequences of inadequate service, such as misdiagnosed problems, incorrect repair procedures, extended equipment downtime, and cascading component failures.

Using non-certified parts creates compatibility issues that compound over time. Aftermarket components may fit poorly, causing excessive wear on surrounding parts. Non-authorized providers cannot guarantee parts availability during critical seasons, potentially extending downtime from days to weeks.

How Does Access to Certified Technicians Affect Reliability?

Access to certified technicians affects reliability by ensuring repairs meet exact manufacturer specifications through specialized training and genuine parts usage. Manufacturer-certified technicians complete rigorous New Holland training programs covering model-specific diagnostics, repair procedures, and preventive maintenance protocols. These technicians use genuine OEM parts with guaranteed fit and quality, preventing recurring failures from ill-fitting alternatives.

Every 1% increase in uptime generates 3-5% revenue boost for commercial operations. Certified technicians achieve higher first-time fix rates through proper diagnosis and repair execution. Their expertise reduces total repair time, minimizing labor costs and equipment rental expenses during breakdowns.

H&R Agri-Power employs over 100 manufacturer-trained technicians receiving continuous education on New Holland innovations. These specialists understand complex interactions between mechanical, hydraulic, and electronic systems. Their knowledge prevents secondary damage from improper repairs, extending equipment lifespan and maintaining resale value.

What Warranty or Support Advantages Do Authorized Dealers Provide?

The warranty or support advantages authorized dealers provide include comprehensive manufacturer coverage, expedited service programs, and flexible payment options protecting operational budgets. Repairs performed at authorized dealerships remain covered under both standard manufacturer warranties and extended protection plans. This coverage eliminates unexpected repair costs that devastate operating margins during equipment failures.

New Holland's Top Service™ program delivers expedited parts and personalized repair solutions during busy seasons. Authorized dealers prioritize warranty repairs, ensuring faster turnaround than independent shops. Extended coverage plans through authorized dealers offer predictable maintenance costs with locked-in pricing.

There are multiple financial protections through authorized channels, such as transferable warranties enhancing resale value, goodwill repairs beyond standard coverage, recall notifications and free remediation, and manufacturer-backed service guarantees. These advantages create a financial safety net protecting commercial operations from catastrophic repair expenses while maintaining consistent equipment performance throughout ownership.

How Can H&R Agri-Power Support Your Efforts to Reduce Downtime?

H&R Agri-Power supports downtime reduction through its network of over 20 employee-owned locations offering comprehensive New Holland services. The dealership provides routine maintenance, complete equipment rebuilds, and fast parts fulfillment during critical agricultural seasons. Their support infrastructure combines manufacturer-certified technicians with 24/7 emergency service capabilities across multiple states.

What Commercial Services Does H&R Agri-Power Offer for New Holland Operators?

H&R Agri-Power offers commercial services including preventive maintenance programs, emergency field repairs, and complete equipment overhauls for New Holland machinery. The dealership maintains over 100 manufacturer-trained technicians across its 20+ locations. Services span tractors, combines, balers, and construction equipment.

Their Top Parts program ensures critical components remain in stock during peak harvest periods. Remote diagnostic capabilities allow technicians to troubleshoot issues before arriving on-site. The company provides flexible financing options through CNH Capital for both parts and service work.

What Are the Key Takeaways About How New Holland Dealers Help Reduce Downtime for Commercial Operations?

The key takeaways about New Holland dealers' downtime reduction strategies are preventive maintenance programs yielding 400% ROI, remote diagnostics cutting response times by 25-42%, and manufacturer-certified technicians ensuring first-visit fixes. Authorized dealers like H&R Agri-Power provide genuine OEM parts that prevent recurring failures.

Their 24/7 emergency service and proactive parts stocking minimize harvest delays. Personal relationships between farmers and dealer representatives prove more valuable than corporate connections alone. Service quality differentiates successful dealers as operators demand greater technical expertise. These combined strategies help commercial operations maintain the 1% uptime increase that generates 3-5% revenue growth.