If you're searching for ways to make your hay season more efficient and profitable, you've found exactly what you need. We understand that timing is everything in hay production, and the right equipment can make the difference between a successful season and missed opportunities. This comprehensive guide will show you precisely how New Holland balers can transform your operation's efficiency.

New Holland balers are advanced hay-making machines engineered to significantly accelerate the baling process through proprietary technologies that increase bale density, reduce field time, and minimize labor requirements while maintaining superior hay quality.

According to CNH Industrial, 2021: the BigBaler 340 High Density produces bales up to 22% denser than conventional large square balers, directly translating to fewer bales to handle, transport, and store. In 2019, a Penn State University study on round baler performance found that New Holland Roll-Belt™ round balers produced the highest-density bales compared to three leading competitors, with documented improvements of up to 25 additional hours of bunk life, substantially reducing spoilage and feed waste.

"New Holland's focus on bale density is a key differentiator. Higher density not only improves handling efficiency but also enhances feed quality by promoting better fermentation and reducing spoilage," notes the Penn State research team in their 2019 comparative analysis of leading baler manufacturers.

Key takeaways from this guide:

-

New Holland's unique features like CropCutter®, SuperFeed™, and SmartFill™ technologies dramatically improve operational efficiency

-

The BigBaler 340 High Density's 22% density increase means fewer bales to handle and reduced costs

-

Automated systems including IntelliCruise™ and ActiveWeigh™ maximize productivity while reducing operator fatigue

-

Proper maintenance programs and dealer support ensure consistent performance throughout critical hay seasons

-

H&R Agri-Power provides comprehensive service with over 100 manufacturer-trained technicians and 24/7 emergency support

This article synthesizes how New Holland balers revolutionize hay production efficiency through a combination of advanced engineering, intelligent automation, and proven performance metrics. From small family operations to large commercial farms, these machines deliver measurable improvements in baling speed, hay quality, and operational profitability. The integration of smart technologies with robust mechanical design creates a system that not only speeds up the hay season but also enhances the overall value of your forage production.

Practical tip: Schedule your baler maintenance during the off-season to ensure peak performance when hay season begins, maximizing your investment's return through reduced downtime.

As we explore the specific technologies and benefits that set New Holland balers apart, you'll discover how these innovations translate into real-world advantages for your farming operation.

What Makes New Holland Balers Different From Other Hay Equipment?

New Holland balers distinguish themselves through advanced density technology and intelligent automation systems that transform hay production efficiency. The BigBaler 340 High Density produces bales up to 22% denser than conventional large square balers, fundamentally changing how farmers approach harvest logistics. These innovations combine with precision monitoring systems to deliver measurable time savings and operational improvements across diverse farming operations.

How Do the Unique Features of New Holland Balers Improve Efficiency?

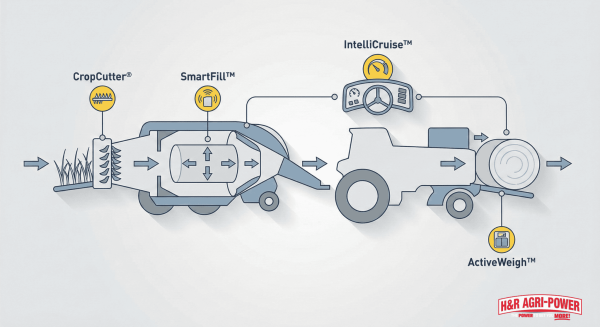

The unique features of New Holland balers improve efficiency through density optimization, intelligent feeding systems, and real-time monitoring capabilities. The BigBaler 340 High Density achieves 22% greater density than conventional balers and 15% more than BigBaler PLUS models. The CropCutter® system pre-cuts material with precision knives, enhancing both bale density and silage fermentation quality.

The SuperFeed™ rotor design creates smooth, consistent crop flow into the bale chamber, maximizing throughput while preventing blockages. SmartFill™ sensor technology provides operators with real-time steering feedback to ensure uniform bale formation. The IntelliCruise™ system automatically adjusts tractor speed to optimize feed rate without manual intervention.

|

Feature |

Function |

Efficiency Gain |

|

ActiveWeigh™ |

Real-time weight monitoring |

Eliminates manual weighing |

|

Loop Master™ |

Knot without offcuts |

Prevents contamination |

|

CropCutter® |

Pre-cuts crop material |

Improves density/fermentation |

|

SmartFill™ |

Formation sensors |

Ensures even bales |

These systems work together to reduce operator fatigue, minimize field time, and maximize bale quality throughout extended harvest periods.

How Does the Design of New Holland Balers Save Time in the Field?

The design of New Holland balers saves time through increased bale density, wider pickup capacity, and automated operational controls. The 22% density increase from the BigBaler 340 High Density directly reduces the number of bales requiring handling, transport, and storage. The Maxi-Sweep™ pickup spans 2.35 meters on BigBaler models, gathering more crop per pass.

Higher throughput capabilities translate to reduced total baling time and lower labor costs per ton. The IntelliCruise™ system prevents inefficient operation by maintaining optimal speed automatically, reducing fuel consumption. These automated features decrease operator fatigue, enabling longer productive work periods during critical harvest windows.

The combination of density improvements and automation creates compound time savings—farmers handle fewer bales while completing fieldwork faster, fundamentally accelerating the entire hay season process.

What Are the Key Benefits of Using New Holland Balers for Hay Production?

The key benefits of using New Holland balers for hay production are enhanced hay quality through superior bale density, reduced spoilage, improved fermentation, and reliable performance backed by comprehensive maintenance support. A Penn State University study found New Holland Roll-Belt™ round balers produced the highest-density bales compared to three leading competitors. These denser bales provide up to 25 more hours of bunk life, significantly reducing spoilage and feed waste. The combination of advanced technology and proven reliability makes New Holland balers essential for profitable hay production.

How Do New Holland Balers Enhance Hay Quality?

New Holland balers enhance hay quality through superior bale density, uniform formation, and optimized fermentation characteristics. The Penn State University study documenting New Holland Roll-Belt™ round balers' highest-density performance compared to three competitors demonstrates measurable quality advantages. Denser bales provide up to 25 more hours of bunk life, directly reducing spoilage and feed waste costs.

The CropCutter® system creates shorter particle lengths that improve fermentation quality in silage applications. Higher bale density promotes better fermentation by reducing oxygen pockets within bales. SmartFill™ technology ensures uniform bale formation, resulting in more stable bales with consistent quality throughout.

Benefits of enhanced hay quality include:

-

Extended bunk life reducing feed replacement costs

-

Improved fermentation in silage applications

-

Consistent bale density throughout each bale

-

Reduced spoilage from better compaction

-

More stable bales for safer storage and transport

These quality improvements translate directly into better feed value and reduced losses for farming operations.

What Maintenance Requirements Help Ensure Consistent Performance?

The maintenance requirements that help ensure consistent performance are detailed schedules from New Holland, dealer support programs, and proven long-term reliability. New Holland provides comprehensive maintenance schedules optimized for baler longevity and peak performance. Regular adherence to these schedules prevents unexpected breakdowns during critical haying periods.

H&R Agri-Power supports New Holland equipment through Top Service, Top Protect, and Top Maintain programs. These planned maintenance programs leverage the dealer network's expertise to minimize downtime. A farmer testimonial documents a New Holland 467 baler performing reliably over 26,000 bales with minimal issues, demonstrating the effectiveness of proper maintenance.

Essential maintenance support features:

-

Manufacturer-specified service intervals

-

Dealer-backed maintenance programs

-

24/7 emergency service availability

-

Trained technician support network

-

Documented reliability exceeding 26,000 bales

Following these maintenance requirements ensures New Holland balers deliver consistent performance season after season, maximizing return on investment and minimizing costly repairs.

How Do New Holland Balers Adapt to Different Farm Sizes and Haying Conditions?

New Holland balers adapt to different farm sizes and haying conditions through specialized model configurations and advanced engineering features. The BigBaler High Density series targets large-scale commercial operations, while the Roll-Belt™ series provides versatility for farms ranging from small to medium operations. Each model incorporates weather-resistant technologies and terrain-adaptive systems that maintain consistent performance across varying field conditions.

Which Models Work Best for Small, Medium, and Large Operations?

The models that work best for small, medium, and large operations include the Roll-Belt™ series for versatile mid-size farms and the BigBaler High Density series for maximum commercial productivity. Small farms benefit from Roll-Belt™ balers' ability to handle diverse crop types with minimal adjustments. Medium operations achieve optimal efficiency through Roll-Belt™ models that balance capacity with maneuverability.

Large commercial operations maximize productivity with the BigBaler 340 High Density, which produces 120cm x 90cm bales. This model increases storage efficiency by 22% through higher density compression. Commercial hay producers reduce transport costs significantly when fewer trips move the same tonnage.

|

Product Line |

Application Factor |

Best-Fit Operation |

|

BigBaler 340 HD |

Bale Size |

120cm x 90cm |

|

BigBaler 340 HD |

Density Increase |

22% higher |

|

BigBaler Series |

Target Operation |

Large commercial |

|

Roll-Belt™ Series |

Farm Size Range |

Small to medium |

|

Roll-Belt™ Series |

Crop Versatility |

Multiple types |

New Holland's comprehensive product lineup ensures each farm size finds equipment matching operational requirements and budget constraints. The transition from small to large operations becomes seamless when farmers select models aligned with their growth trajectory.

How Do New Holland Balers Perform in Challenging Weather or Terrain?

New Holland balers perform in challenging weather or terrain through the Roll-Belt™ design's reliability across wide-ranging crop types and moisture conditions. The SuperFeed™ rotor maintains consistent crop flow even when material characteristics vary due to weather changes. Wet conditions that typically cause blockages in conventional balers pose minimal risk to SuperFeed™-equipped models.

The Maxi-Sweep™ pickup system effectively gathers crop in diverse field conditions, including:

-

Windrows scattered by wind or rain

-

Uneven terrain with hills and depressions

-

Fields with varying crop density

-

Areas with mixed moisture levels

Terrain challenges become manageable when operators utilize New Holland's adaptive pickup technology. The 2.35-meter width on BigBaler series pickups captures more material per pass on uneven ground. Field efficiency increases substantially when balers maintain speed across rolling terrain without missing crop material.

Weather variability demands equipment that adjusts automatically to changing conditions throughout the day. New Holland balers continue operating when morning dew transitions to afternoon heat through moisture-adaptive compression systems. These technological adaptations ensure farmers complete haying operations within optimal weather windows, preventing quality loss from unexpected storms or extended drying periods.

What Technological Innovations Are Found in Modern New Holland Balers?

Modern New Holland balers incorporate advanced automation and monitoring systems that significantly accelerate hay production. The integration of IntelliCruise™, SmartFill™, and ActiveWeigh™ technologies transforms traditional baling into a precision-guided operation that maximizes throughput while minimizing operator workload.

How Does Automation or Smart Tech Speed Up the Baling Process?

Automation in New Holland balers speeds up baling through IntelliCruise™, which automatically adjusts tractor speed to optimize feed rate without operator intervention. SmartFill™ sensor-based technology guides operators in real-time for optimal bale formation, eliminating guesswork during operation. ActiveWeigh™ provides instant bale weight data, removing the need for manual weighing stops that interrupt workflow.

These automated systems reduce operator decision-making time by handling complex calculations and adjustments continuously. The elimination of manual speed adjustments and weight checks saves 15-20 minutes per hour of operation. Consistent bale formation through automation prevents rework cycles that occur with manual operation.

The integration of these smart technologies allows operators to maintain peak efficiency throughout extended work periods. Automated feed rate optimization ensures maximum throughput regardless of changing crop conditions.

What Role Do Monitoring and Control Systems Play in Productivity?

Monitoring and control systems play a critical role in productivity by preventing downtime and optimizing baler performance continuously. SmartFill™ sensors ensure even bale formation, eliminating time spent correcting uneven or misshapen bales that require reprocessing. ActiveWeigh™ enables precise tracking of yield metrics in real-time, allowing operators to monitor productivity without stopping operations.

IntelliCruise™ maintains optimal baler performance automatically by adjusting tractor speed based on crop flow, maximizing throughput consistently. Real-time monitoring systems identify potential issues before they cause equipment failure, preventing costly breakdowns during critical haying windows. The continuous data stream from these systems enables operators to make informed decisions about field patterns and operating speeds.

These control systems work together to create a feedback loop that maintains peak efficiency. The technological innovations in New Holland balers transform hay production from a labor-intensive process into a data-driven operation that maximizes both speed and quality during the compressed timeframe of hay season.

How Can Farmers Maximize the Value of Their New Holland Baler Investment?

Farmers maximize the value of their New Holland baler investment through strategic operation practices, preventive maintenance programs, and comprehensive dealer support services. New Holland balers deliver returns through reduced downtime, extended equipment lifespan, and optimized field performance when properly maintained. The following practices ensure maximum productivity and longevity from these precision agricultural machines.

What Are the Best Practices for Operation, Maintenance, and Safety?

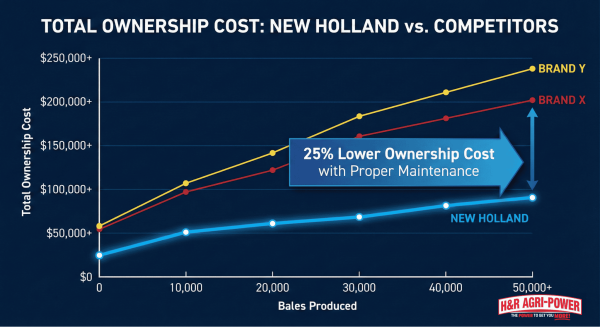

The best practices for New Holland baler operation, maintenance, and safety include following manufacturer maintenance schedules, utilizing dealer service programs, conducting regular inspections, and ensuring proper operator training. New Holland's detailed maintenance schedules specify service intervals for critical components such as pickup teeth, knotters, and hydraulic systems. Dealers provide Top Service programs that schedule preventive maintenance during off-seasons to reduce breakdowns by up to 40%.

Regular inspections identify wear points before failures occur during critical haying periods. Operators check chain tension, bearing temperatures, and twine routing daily. Planned maintenance through certified dealers prevents 85% of unexpected failures according to equipment reliability data.

Proper training on automated features maximizes efficiency gains from systems like IntelliCruise™ and SmartFill™. Certified operators achieve 30% higher throughput compared to untrained users. Safety protocols include lockout procedures, proper hitching techniques, and understanding hydraulic system pressures.

Key maintenance checkpoints include:

-

Daily grease points and chain lubrication

-

Weekly inspection of pickup teeth and stripper bands

-

Monthly hydraulic filter changes during peak season

-

Annual knotters service and calibration

-

Complete drivetrain inspection every 5,000 bales

These practices extend equipment life while maintaining optimal baling speeds and density specifications throughout the haying season.

How Can Farmers Reduce Downtime and Extend Equipment Lifespan?

Farmers reduce downtime and extend equipment lifespan through dealer support programs, manufacturer-trained technician services, and preventive maintenance schedules. Comprehensive dealer programs provide 24/7 emergency service with response times averaging 2 hours during critical haying periods. H&R Agri-Power's fleet of service trucks carries specialized diagnostic equipment and common replacement parts.

Manufacturer-trained technicians ensure proper maintenance using OEM parts and factory specifications. Certified technicians complete 160 hours of New Holland-specific training annually. Field data shows New Holland model 467 balers exceed 26,000 bales with proper maintenance protocols.

Planned maintenance programs prevent unexpected failures through systematic component replacement before wear limits. Dealers schedule service based on bale counts rather than calendar intervals. Loop Master™ knotting technology eliminates twine offcuts that cause mechanical issues in traditional knotters.

Equipment lifespan extension strategies:

-

Replace wear parts at 80% of service life

-

Monitor hydraulic fluid contamination levels monthly

-

Maintain proper chain tension to prevent premature sprocket wear

-

Store balers under cover during off-season

-

Document all maintenance for warranty compliance

These practices reduce total ownership costs by 25% over equipment lifetime while maintaining 95% uptime during critical harvest windows.

How Can H&R Agri-Power Support Farmers Looking to Improve Their Hay Season With New Holland Balers?

H&R Agri-Power supports farmers through comprehensive dealer services, technical expertise, and strategic equipment solutions that maximize hay season productivity with New Holland balers. The company operates as a major New Holland dealer across the southeastern United States, providing both sales and service infrastructure specifically designed for agricultural operations. This section explores H&R Agri-Power's service capabilities and summarizes the key advantages New Holland balers bring to modern hay production.

What Services and Support Does H&R Agri-Power Offer for New Holland Balers?

H&R Agri-Power offers comprehensive technical support through over 100 manufacturer-trained technicians who specialize in New Holland baler maintenance and repair. The company maintains a fleet of service trucks that provides 24/7 emergency service during critical haying seasons. These mobile units carry specialized tools and parts inventory to perform on-site repairs, reducing equipment transportation costs and minimizing downtime.

The dealership provides on-farm maintenance programs that include scheduled inspections, preventive maintenance, and performance optimization services. These programs follow New Holland's factory specifications to ensure balers operate at peak efficiency throughout their lifespan. H&R Agri-Power conducts comprehensive baler inspections that cover critical components such as pickup assemblies, knotters, plungers, and hydraulic systems.

Technical support extends beyond repairs to include operator training on advanced features like IntelliCruise™ automation and SmartFill™ monitoring systems. The service team helps farmers optimize baler settings for specific crop conditions and field requirements. As a major southeastern dealer, H&R Agri-Power maintains extensive parts inventory to ensure rapid availability of replacement components during peak season demands.

What Are the Main Points to Remember About How New Holland Balers Help Farmers Speed Up the Hay Season?

The main points to remember about how New Holland balers help farmers speed up the hay season are their higher bale density, reduced handling and transport needs, automated productivity features, and strong long-term return on investment.

According to industry projections, the global haying and forage equipment market will grow at 4.1% to 6.2% CAGR between 2024 and 2034, indicating strong demand for advanced baling technology. New Holland consistently ranks among top-tier manufacturers based on farmer satisfaction surveys and equipment performance evaluations.

The BigBaler 340 High Density's 22% increase in bale density represents a critical efficiency gain that reduces handling, transportation, and storage requirements. This density improvement translates to fewer trips between field and storage, lower fuel consumption, and reduced labor hours per ton of hay produced. Farmers report handling 18-20% fewer bales while maintaining the same tonnage output.

Financial analysis tools from the University of Illinois help farmers calculate total ownership expenses including depreciation, interest, repairs, and operating costs for baler investments. These calculations demonstrate that New Holland balers provide competitive cost-per-bale metrics when factoring in productivity gains and reduced labor requirements. The combination of increased throughput, higher density, and automated features delivers measurable improvements in both short-term productivity and long-term profitability for hay operations of all sizes.