If you're researching agricultural equipment history or considering New Holland machinery for your farming operation, you've found the definitive resource on this remarkable company's 130-year journey.

We understand that choosing the right equipment partner requires knowing their heritage, innovation track record, and commitment to agriculture—and that's precisely why we've compiled this comprehensive history of New Holland's transformation from a Pennsylvania blacksmith shop to a global agricultural powerhouse.

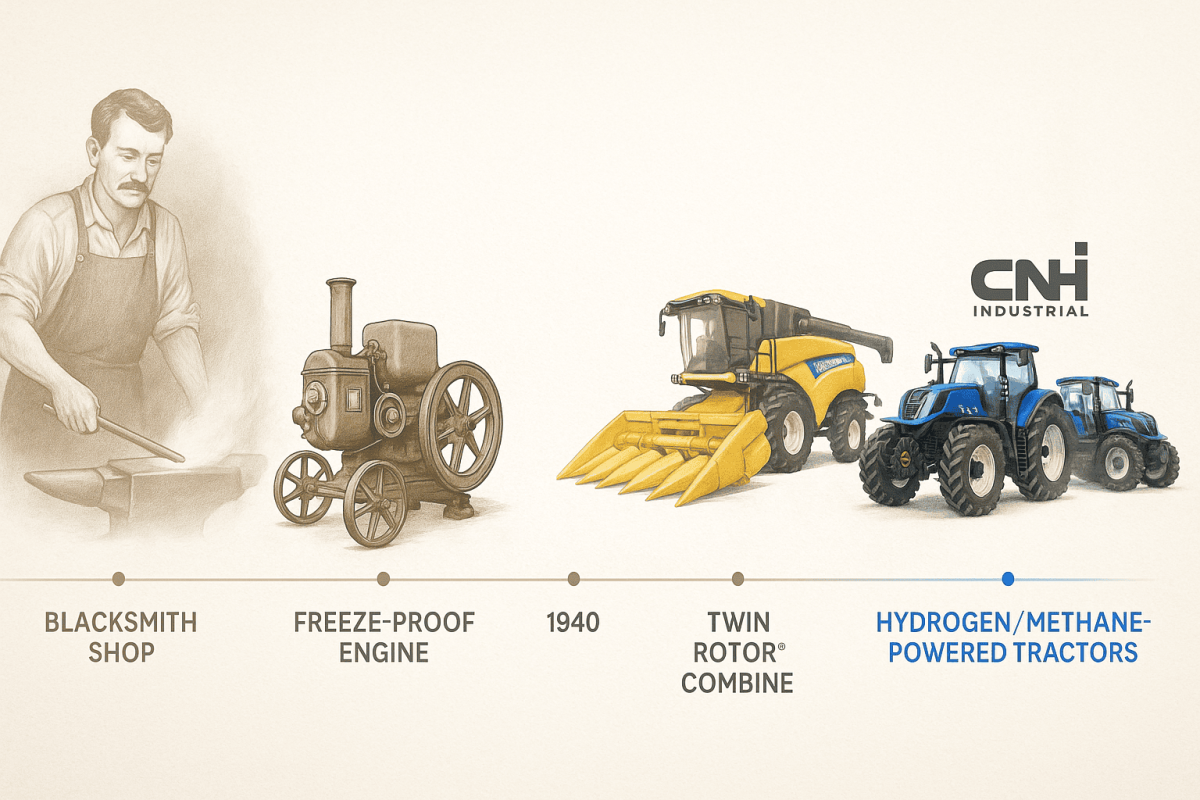

The history of New Holland is a testament to American innovation and agricultural advancement, beginning when Abe Zimmerman founded a blacksmith shop in New Holland, Pennsylvania in 1895, officially incorporating the New Holland Machine Company in 1903 with a revolutionary freeze-proof engine that solved critical winter operation problems for farmers.

According to the Lancaster Farming archives from 2020, New Holland's employment grew from a one-man operation in 1895 to 40-50+ employees by the 1920s-1930s, with the company now part of CNH Industrial operating in 170 countries with 35,850 employees and generating $19.8 billion in revenue as of 2024.

Our exploration reveals key breakthroughs including Zimmerman's 1903 freeze-proof engine patent, Nolt's revolutionary automatic baler development in 1936-1937, the game-changing Twin Rotor® combine technology in 1975, strategic acquisitions from Sperry Rand (1947) through CNH Global formation (1999), and pioneering sustainable farming innovations like the NH2™ hydrogen tractor (2009) and methane-powered equipment achieving 98% particulate matter reduction.

This comprehensive history traces New Holland's evolution through strategic mergers with industry giants like Ford ($1.965 billion combined sales in 1986) and Case Corporation, examines their technological innovations that revolutionized harvesting efficiency by up to 30%, details their expansion from Pennsylvania to 37 manufacturing facilities across 170 countries, analyzes their current 27.1% global market share position, and showcases their commitment to sustainable agriculture through zero-emission hydrogen tractors and biogas-compatible methane equipment that enables 10-15% CO2 reduction.

The following sections detail New Holland's founding story, technological milestones, global expansion strategy, and how H&R Agri-Power continues this legacy of agricultural innovation across the United States, providing you with the complete picture needed to understand why New Holland remains a trusted partner for farmers worldwide after 130 years of continuous innovation.

What Were the Origins of New Holland and Who Founded the Company?

The origins of New Holland trace back to 1895 when Abe Zimmerman founded a blacksmith shop in New Holland, Pennsylvania. The New Holland Machine Company was officially incorporated in 1903 with a patented freeze-proof engine. Zimmerman earned recognition as "a clever man and a good machinist... quick to take up a new idea and had the ability to make it work."

The company transformed from a one-man operation in 1895 to employing 40-50+ workers by the 1920s-1930s. George Delp served as president in 1947 and established the silver dollar Christmas bonus tradition. The following subsections explore how local agricultural conditions shaped early development and detail the first products that launched New Holland's growth.

How Did the Local Agricultural Environment Influence New Holland's Early Years?

The local agricultural environment influenced New Holland's early years through Lancaster County's farming communities that needed equipment repairs and innovations. Edwin B. Nolt, a local Mennonite farmer, developed the automatic baler prototype during winter 1936-1937. Nolt registered his 61 total patents as "A Lancaster County Farmer" due to Mennonite community privacy preferences.

The agricultural setting enabled immediate field testing, with Nolt using his prototype baler in custom cutting operations in 1937. Lancaster County's concentrated farming operations provided direct customer feedback and rapid innovation cycles. This proximity to end users accelerated product development and established New Holland's reputation for practical agricultural solutions.

What Were the First Products Developed by New Holland?

The first products developed by New Holland included the freeze-proof 1.5 HP engine in 1903, which solved winter freezing issues for farmers. The company launched a 3 HP gasoline engine on wheeled trucks in 1908 for portable power applications.

Early product lines expanded to include feed mills, rock crushers, and stationary engines. The Model 73 automatic pickup baler introduced in 1940 became the first commercially successful automatic baler. Nolt's baler patent (US2236628A) was granted in 1941, establishing New Holland's leadership in hay harvesting technology.

These foundational products addressed specific agricultural challenges and positioned New Holland as an innovator in farm mechanization solutions.

How Did Technological Innovations Shape New Holland's Growth?

Technological innovations shaped New Holland's growth by transforming labor-intensive farming into mechanized operations. The 1940 Model 73 automatic baler reduced labor requirements from three-person manual teams to single-operator systems.

In 1975, New Holland introduced the Twin Rotor® TR70 combine with 145-168 HP and revolutionary rotary harvesting technology that "changed the face of harvesting forever" according to industry consensus. A 2022 study by Peng et al. (147 citations) demonstrates direct correlation between mechanization advances and enhanced production capacity.

New Holland projects automation efficiency improvements of up to 30% by 2025 through continued innovation. The upcoming sections detail specific milestones and mechanization contributions that built New Holland's technological foundation.

What Were the Major Milestones in New Holland's Product Development?

The major milestones in New Holland's product development span from early engines to modern guidance systems. In 1903, the company launched a freeze-proof 1.5 HP engine solving critical winter operation problems.

The Model 73 automatic pickup baler in 1940 launched commercial baler production. New Holland introduced the Twin Rotor® TR70 combine with rotary harvesting technology in 1975. Development of the NH2™ hydrogen tractor began in 2009.

The company unveiled its methane-powered tractor concept on August 29, 2017. In 2024, New Holland's LIDAR guidance system won the EIMA Technical Innovation Award. The Twin Rotor® technology celebrates its 50th anniversary in 2025.

How Did New Holland Contribute to Agricultural Mechanization?

New Holland contributed to agricultural mechanization through transformative baler and combine technologies. Baler production evolved from single-unit manufacturing in the 1940s to thousands of units annually today.

According to a 2024 study by Meng et al., mechanization significantly improved labor productivity across farming operations. Combines reduced harvest time from days of manual work to hours of mechanized operation.

Edwin B. Nolt's 1956 patent US2750877A for automatic pick-up balers influenced 6 subsequent patents in agricultural machinery. Production scale expanded from a single Pennsylvania shop to 37 manufacturing facilities globally. These mechanization advances enabled farmers to increase acreage and reduce labor costs while maintaining quality standards.

When Did New Holland Expand Beyond Its Original Location?

New Holland expanded beyond its original location beginning in 1947 when Sperry Rand Corporation acquired the company. This acquisition transformed New Holland from a regional Pennsylvania manufacturer into a national U.S. distributor with expanded network capabilities.

The 1964 acquisition of Claeys in Belgium marked the company's first major international expansion, establishing a European manufacturing presence. By the 1970s, during New Holland's 75th anniversary period, international dealer network development accelerated significantly.

Today, New Holland operates in 170 countries through 11,500+ dealers and distributors, with manufacturing expanded from one Pennsylvania plant to 37 facilities globally while maintaining production in the original New Holland town.

How Did New Holland Enter International Markets?

New Holland entered international markets through strategic acquisitions and mergers that built global distribution networks. The 1964 Claeys acquisition in Belgium represented the first major international expansion, with the Belgian threshing machine specialist rebranded as Clayson.

In 1986, the Ford New Holland merger created a combined network of approximately 2,700 dealerships globally. The 1991 Fiat acquisition brought established European manufacturing and distribution strength to New Holland operations.

The 1999 formation of CNH Global through the Case Corporation merger expanded its presence to 170 countries. Most recently, the 2017 Kongskilde acquisition strengthened New Holland's European implement market position, demonstrating continued international growth strategy.

What Strategies Enabled New Holland's Global Reach?

The strategies that enabled New Holland's global reach centered on strategic mergers that created overlapping dealer networks and combined expertise. By 1985, approximately 400 dealers carried both Ford and New Holland brands, maximizing market coverage.

The combined Ford-New Holland entity generated $1.965 billion in sales, with Ford Tractor contributing $1.25 billion and New Holland $715 million in 1984. Fiat's agricultural division expertise, established in 1918 with the Fiat 702 tractor, accelerated European growth post-1991.

CNH Industrial now maintains 56 R&D centers worldwide for localized innovation and product development. The company operates 12 company-owned dealerships in North America and Europe for direct market insight and customer feedback integration.

What Role Did Mergers and Acquisitions Play in New Holland's Expansion?

Mergers and acquisitions played a transformative role in New Holland's expansion from a regional equipment manufacturer to a global agricultural powerhouse. The 1947 Sperry Rand acquisition marked New Holland's shift from regional to national operations.

Ford's 1986 acquisition created Ford New Holland with $1.965 billion in combined pre-merger sales. Fiat's 1991 purchase formed N.H. Geotech, gaining full control by 1993. The 1999 Case Corporation merger established CNH Global as an industry giant.

CNH Industrial formed in 2013 following the Iveco demerger, generating $19.8 billion revenue in 2024. These strategic moves expanded New Holland's dealer networks, manufacturing capabilities, and product portfolios across 170 countries.

Which Key Companies Merged with or Were Acquired by New Holland?

The key companies that merged with or were acquired by New Holland are Sperry Rand Corporation (1947), Claeys of Belgium (1964), Ford Tractor Operations (1986), Case Corporation (1999), and Kongskilde (2017).

Sperry Rand Corporation acquired New Holland in 1947, enabling national expansion beyond Pennsylvania. Claeys, founded in 1906 and specializing in threshing machines, joined through Sperry's 1964 acquisition.

Ford Tractor Operations merged in 1986, contributing 1,400 North American dealers to the network. Case Corporation, established in 1842, merged in 1999 to form CNH Global. Kongskilde's 2017 acquisition strengthened the implements portfolio.

How Did These Business Moves Impact Its Product Offerings?

These business moves impacted New Holland's product offerings by expanding technology, expertise, and brand portfolios. Claeys acquisition added European combine harvester expertise and advanced threshing technology.

Ford's merger expanded the tractor line through Ford's $1.25 billion tractor operation experience and established dealer relationships. The Case merger created a comprehensive product portfolio spanning all agricultural segments including tillage, planting, and harvesting equipment. CNH Industrial now operates multiple brands including New Holland Agriculture, Case IH, Steyr, and Raven.

The combined entity holds 7,700+ patents driving continuous innovation across product lines. Each acquisition brought specialized knowledge that enhanced New Holland's ability to serve diverse global agricultural needs.

How Has New Holland Influenced Modern Agriculture Worldwide?

New Holland influences modern agriculture worldwide through CNH Industrial's commanding 27.1% global market share, combining New Holland and Case IH brands. The company topped global market share rankings for two consecutive years from 2020 to 2021.

Twin Rotor® combines demonstrate this influence by unloading 6 bushels per second with 567-bushel grain tank capacity. A 2022 mechanization impact study by Peng et al. demonstrates improvements in productivity and income from agricultural mechanization.

The global agricultural equipment market projects growth to $291.3 billion by 2030 from $172 billion in 2024. New Holland's innovations in sustainable farming and precision agriculture shape how farmers worldwide approach modern agricultural challenges.

What Signature Innovations Are Associated with New Holland?

Signature innovations associated with New Holland include Twin Rotor® technology, alternative fuel tractors, and precision farming systems. Twin Rotor® technology revolutionized harvesting in 1975 with 22-inch diameter, 104-inch length rotors.

The CR11 flagship combine delivers 775 horsepower with Harvest Suite™ Ultra cab. NH2™ hydrogen tractor achieves zero-emission operation following development since 2009. Methane-powered tractors reduce particulate matter by 98% versus diesel engines.

The LIDAR guidance system won the 2024 EIMA Award and enables GPS-free precision farming. ForageCam™ and Corn Header Automation earned 2025 Agritechnica Innovation silver medals. These technologies transform harvest efficiency, environmental impact, and operational precision across global farming operations.

In What Ways Does New Holland Support Sustainable Farming Today?

New Holland supports sustainable farming today through alternative fuel programs, emission reductions, and precision agriculture systems. Methane tractors enable 10-15% CO2 reduction using farm waste biogas.

CNH Industrial achieved 35.5% operational emissions reduction in 2023 versus 2018 baseline. Precision agriculture systems optimize input use and reduce waste through targeted application. The energy-independent farm model promotes circular economy with on-farm biogas production.

IntelliView™ terminal systems enable data-driven decision-making for resource optimization. Alternative fuel programs span 16 years for hydrogen development and 8 years for methane technology. These initiatives position New Holland as a leader in agricultural sustainability while maintaining operational efficiency for farmers worldwide.

How Can H&R Agri-Power Customers Experience New Holland's Legacy and Innovations?

H&R Agri-Power connects farmers to New Holland's 129-year legacy, by offering New Holland products at 6 of the 21 dealership locations across Alabama, Illinois, Indiana, Kentucky, Mississippi, and Tennessee. The dealership network generated $739.7 million in revenue during 2023, surpassing New Holland's entire 1984 company sales of $715 million.

Customers access the complete New Holland product line through this Employee Stock Ownership Plan (ESOP) company that employs 599 people and maintains an 85.11% absorption rate compared to the 82.7% industry average.

What New Holland Products and Services Does H&R Agri-Power Offer Nationally?

H&R Agri-Power offers the full New Holland equipment portfolio including tractors, combines, balers, and precision agriculture technology across its multi-state network. The dealership holds 24.77% cash crop market share and 38.32% livestock market share in its operating territories.

Founded through the 1993 merger of H&R Implement (established 1959) and Agri-Power Inc. (established 1990), the company ranks #30 in the Farm Equipment Dealer 100. Service capabilities include factory-trained technicians, genuine New Holland parts inventory, and precision agriculture support systems.

The dealership network provides financing options through CNH Industrial Capital and maintains 24-hour parts availability during peak seasons.

What Are the Key Takeaways about the History and Impact of New Holland?

The key takeaways about New Holland's history demonstrate transformation from Abe Zimmerman's one-man blacksmith shop in 1895 to a division of the $19.8 billion CNH Industrial corporation in 2024.

New Holland operates across 170 countries with 35,850 employees following the Iveco demerger. The company maintains 37 manufacturing plants and 56 R&D centers globally while holding approximately 10% of the global tractor market.

CNH Industrial ranks as the 7th largest machinery manufacturer worldwide. Market projections indicate the round hay baler segment will reach $2,035.4 million by 2033 with 4.3% compound annual growth rate. This global reach enables H&R Agri-Power customers to access world-class agricultural innovation backed by century-spanning expertise.