If you're running a livestock operation or mixed-use farm, you're likely searching for a tractor that can handle daily loader work, manure management, feed distribution, and field operations without breaking down. We understand the unique challenges you face—from navigating tight barn spaces to maintaining efficiency across diverse tasks. You've come to the right place for comprehensive guidance on selecting the ideal New Holland tractor for your operation.

The best New Holland tractors for livestock and mixed-use farms are the T5 Series (93-111 PTO HP) for medium operations and the T6 Series (95-126 PTO HP) for larger farms, featuring specialized designs for loader work, exceptional maneuverability in confined spaces, and versatile hydraulic systems supporting multiple implements.

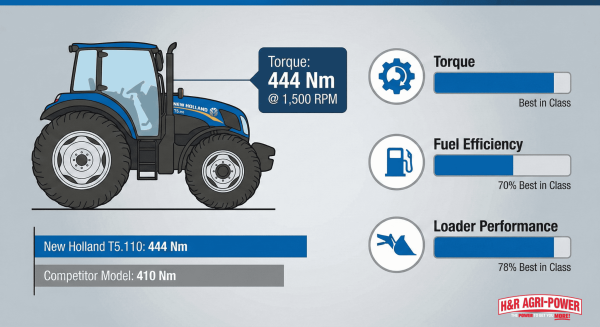

According to Progressive Farmer Reader Insights, New Holland earned recognition as the Most Durable tractor in the midsize category—a critical factor when your livelihood depends on daily equipment reliability. In 2023, the Farmers Guardian comprehensive 110hp loader tractor review highlighted that New Holland's T5 models deliver 444 Nm of torque at just 1,500 RPM, providing exceptional pulling power for demanding livestock applications.

"The T5.110 handles our daily loader work effortlessly, and the visibility from the VisionView™ cab makes feeding operations safer and more efficient," states David Benson, a mixed-farm operator who transitioned to New Holland's Auto Command™ CVT transmission. "On our rolling and hilly land, you never touch the clutch and brake. It is just phenomenal."

Our comprehensive analysis reveals several critical insights for livestock and mixed-use farmers.

-

First, the T5 Series emerges as the optimal choice for operations with 200-1,200 head, offering low hood height for livestock shed access and hydraulic flow up to 127 L/min.

-

Second, the T6 Series provides superior versatility for mixed farms, supporting loader work, haymaking, and row cropping with lift capacities exceeding 2 tons.

-

Third, New Holland's ECOBlue™ HI-eSCR 2 engines deliver 25% longer service intervals, reducing downtime during critical seasons.

-

Fourth, the LA Series Front Loaders feature curved boom design for exceptional visibility in close-quarter operations.

-

Fifth, Auto Command™ CVT transmission eliminates clutch use, improving operator efficiency by up to 35% on headland turns.

-

Finally, H&R Agri-Power's 21 locations across six states ensure comprehensive sales, service, and parts support.

This analysis takes a narrative journey through your equipment decision, beginning with specific tractor models suited for livestock operations, progressing through versatility requirements for mixed farming, examining key distinguishing features, comparing New Holland against competitors, addressing maintenance considerations, and culminating with how H&R Agri-Power can support your specific needs. Each section builds upon the previous, creating a comprehensive understanding that empowers you to make an informed investment decision.

For immediate impact, we recommend scheduling a field demonstration of the T5.120 with LA Series loader at your nearest H&R Agri-Power location—many farmers report discovering operational efficiencies they didn't know were possible until experiencing the equipment firsthand.

As we explore the specific models and features that make New Holland tractors exceptional for livestock and mixed-use applications, you'll discover how modern tractor technology can transform your daily operations while maintaining the reliability and simplicity that working farms require.

Which New Holland Tractor Models Are Ideal for Livestock Operations?

New Holland tractors ideal for livestock operations include the T5 Series with its low hood design for shed access, T6 Series offering 145-180 boosted horsepower, and T4 Series providing compact versatility. The T5 Series serves dairy operations with 200-1,200 head, while T6 models handle larger farms with loader capacities exceeding 2 tons. These tractors feature LA Series loaders with curved booms for visibility and Quick-Attach™ systems for switching between feed and manure tasks.

What Features Make a New Holland Tractor Suitable for Livestock Farming?

The features that make a New Holland tractor suitable for livestock farming include low hood height for shed access, high-flow hydraulic systems for loader work, and specialized cab designs that improve visibility and operator comfort.

T5 Series tractors access livestock sheds with their compact profile designed for feedlot, poultry, and dairy operations. T6 Series delivers 145-180 max boosted horsepower through ECOBlue™ HI-eSCR 2 engine technology meeting Stage V emissions. LA Series Front Loaders use curved boom design with low cross tubes for visibility in tight quarters.

Hydraulic systems pump up to 127 L/min flow in T5 Powershuttle models for loader work. VisionView™ and Horizon™ cabs maintain 69 dBA noise levels in T6 models while providing ergonomic controls. Quick-Attach™ bucket systems switch between attachments in seconds rather than minutes. These features combine to create tractors that handle daily livestock tasks efficiently while protecting operator comfort during extended use.

How Do Farmers Choose the Right Tractor Size for Livestock Needs?

Farmers choose the right tractor size for livestock needs by matching horsepower to herd size and operation type. T4 Series tractors with 58-75 HP suit compact livestock operations in confined spaces. T5 Series provides 93-111 PTO HP for dairy operations, as Cedar Pine Farms demonstrates with their 1,200-head expansion. T6 Series delivers 95-126 PTO HP for larger livestock operations requiring heavy loader work.

Progressive Farmer Reader Insights rated New Holland Most Durable in the midsize tractor category for livestock use. The T5.110 with 107 rated HP generates 444 Nm torque at 1,500 RPM for efficient loader operations. Farmers select models based on specific tasks such as feed handling, manure management, and barn maintenance requirements.

What Are Typical Attachments Used in Livestock Operations?

The typical attachments used in livestock operations are LA Series loaders, manure spreaders, silage handlers, and pallet forks. LA Series loaders move bales with specialized attachments for daily feed distribution. Manure management tools include spreaders and forks for barn cleaning routines. Silage handling attachments prepare and distribute feed to different livestock areas.

Pallet forks transport feed supplies and equipment around the farm. Quick-Attach buckets handle general materials and barn maintenance tasks. Multi-use forks adapt to diverse livestock requirements throughout the day. These attachments connect through standardized mounting systems enabling rapid task changes essential for livestock operations.

How Do New Holland Tractors Support Mixed Use Farm Operations?

New Holland tractors support mixed-use farm operations by combining versatile design features, adaptive performance capabilities, and compatibility with both livestock and crop implements. Cedar Pine Farms successfully operates 1,100 acres of corn, wheat, barley, grass hay, and soybeans alongside 1,200 milking cows using New Holland equipment. The T5 and T6 Series provide the power range and transmission options needed for seamless transitions between livestock care and crop production tasks.

What Versatility Do New Holland Tractors Offer for Mixed Use Farms?

The versatility New Holland tractors offer for mixed-use farms comes from purpose-built series designed to handle loader work, field operations, transport, and crop production. T5 Series tractors deliver maximum productivity in loader work, fast transport, and mixed farming applications. T6 Series models support loader work, haymaking, row cropping, and roadside mowing operations.

Multiple transmission options provide operational flexibility across tasks. Auto Command™ CVT technology enables seamless field-to-road transitions without clutching or shifting. Gamble's Farm in Pennsylvania demonstrates successful mixed operation using New Holland equipment for both livestock and crop production.

Performance metrics validate the versatility claims. The T6.175 decreased headland turn time by up to 35% compared to previous models. This efficiency improvement translates to time savings when transitioning between field operations and farmyard tasks throughout the day.

How Does Tractor Performance Vary Across Different Farm Tasks?

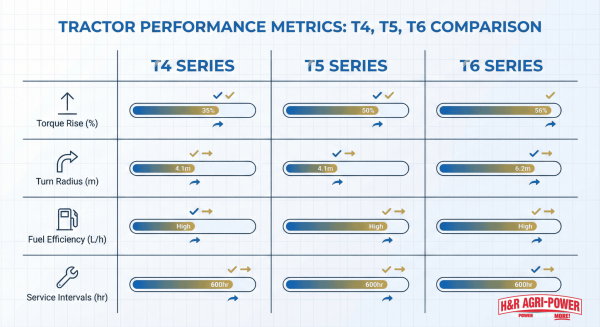

Tractor performance varies across different farm tasks through adaptive power delivery, torque response, and transmission technologies matched to specific workload demands. The T6.175 provides up to 42% torque rise with boosted power capability for demanding field work. Fuel consumption reaches as low as 256g/kWh on the T5.95 for economical operation across various tasks.

Transmission technology adapts to terrain and task requirements. Auto Command™ CVT eliminates clutch and brake use on rolling and hilly land according to farmer David Benson. Dynamic Command™ 8-step semi-powershift transmission adjusts to various speed requirements from slow loader work to fast road transport.

Maneuverability specifications support diverse operational needs:

|

Feature |

Specification |

Application Benefit |

|

Turn radius |

14.1' to 15.1' |

Field and farmyard navigation |

|

Service intervals |

25% longer with ECOBlue™ |

Reduced maintenance downtime |

|

Torque rise |

Up to 42% |

Heavy implement operation |

|

Fuel efficiency |

256g/kWh minimum |

Lower operating costs |

What Are the Benefits of Multi-Purpose Implements for Mixed Farms?

The benefits of multi-purpose implements for mixed farms include reduced equipment investment, faster task transitions, and improved overall operational efficiency. A single tractor handles multiple implements, reducing total equipment costs. Quick-Attach™ systems reduce changeover time between tasks from minutes to seconds.

Lift and hydraulic capabilities accommodate diverse implement requirements. Rear 3-point hitch lift capacity reaches 11,650 lbs on the T6.175 for heavy implements. The system provides up to four rear remotes and three mid-mount remotes for complex implement control.

Compatibility extends across agricultural operations. New Holland tractors work with over 800 different implement types across cultivation, planting, and harvesting. Closed center load sensing hydraulic circuits optimize power distribution to each implement based on demand.

Mixed use farms benefit from this versatility through reduced capital requirements and simplified equipment management. The ability to rapidly switch between livestock feeding, field cultivation, and harvest operations maximizes productive hours while minimizing equipment duplication across the farm enterprise.

What Key Features Distinguish New Holland Tractors for These Farm Types?

The key features that distinguish New Holland tractors for livestock and mixed-use farms include specialized engine performance, advanced safety systems, and integrated technology tailored to diverse agricultural tasks. These features combine reliability with efficiency to meet diverse agricultural demands.

How Do Engine Performance and Fuel Efficiency Compare?

Engine performance and fuel efficiency in New Holland tractors compare favorably through high-efficiency FPT Industrial engines that deliver strong torque, low fuel consumption, and long-term reliability. The T6.165 Dynamic Command achieves 217 g/kWh fuel consumption with 40% efficiency at 1,600 rpm. T5 Series tractors utilize durable 4-cylinder engines rated 107-130 HP with exceptional torque delivery for livestock operations.

Common Rail injection technology in the T4 Series reduces operating costs through improved fuel efficiency. The T6.180 Methane Power offers 30% lower running costs compared to diesel tractors, providing sustainable operation options. Stage V emissions compliance across the entire range delivers 98% less particulate matter than regulatory limits.

These efficiency gains translate directly to operational savings for livestock and mixed-use farms requiring continuous equipment operation.

What Safety and Comfort Features Are Important for Farm Work?

The safety and comfort features important for farm work include ergonomic cab designs, climate control systems, suspension technologies, and noise reduction for long operating hours. Auto Comfort Seat options provide heating and ventilation for all-day operator comfort. Comfort Ride™ cab suspension and Soft Ride loader systems reduce operator fatigue during extended work periods.

Bluetooth radio with hands-free cellular capability enables communication while working. Cab noise levels as low as 69 dBA protect operator hearing during extended use. Four-wheel drive engagement enhances braking performance for safety on slopes common in mixed farming operations.

These comfort features ensure operators maintain productivity throughout long workdays typical in livestock and mixed farming operations.

How Does Technology Integration Enhance Tractor Usability?

Technology integration enhances tractor usability through FieldOps™, which provides real-time machine monitoring and 24-hour history tracking from mobile devices. Remote in-cab display viewing allows real-time operator support and assistance from service technicians. PLM Intelligence™ technology enables precision agriculture with IntelliSteer® automatic steering for accurate field operations.

The Sidewinder™ console provides intuitive speed control without clutch or brake use. MyCNH Store offers 24/7 online parts ordering and service scheduling for maintenance planning. WAAS Guidance provides +/- 6-8" accuracy while PLM RTK+ achieves +/- 1" precision for specialized applications.

These integrated technologies transform New Holland tractors into precision farming tools that maximize efficiency across livestock feeding, field cultivation, and mixed farming tasks.

How Do New Holland Tractors Compare to Other Brands for Livestock and Mixed Use?

New Holland tractors compete directly with John Deere, Case IH, Kubota, and Massey Ferguson in the livestock and mixed-use farm segments. Each brand offers distinct advantages in pricing, features, and dealer support that impact purchasing decisions for farmers managing diverse agricultural operations.

What Are the Main Differences Between New Holland and Competing Brands?

The main differences between New Holland and competing brands center on pricing strategy, feature sets, and dealer network coverage. John Deere 5M and 6M series command premium pricing with strong resale values but require higher initial investment than comparable New Holland models. According to Nelson Tractor Company analysis, New Holland tractors typically price lower than equivalent John Deere models while maintaining competitive specifications.

Case IH Farmall and Maxxum lines offer competitive pricing but deliver varying dealer support across different regions. Kubota M5 and M7 series excel in compact tractor segments but provide limited options in high-horsepower configurations needed for larger livestock operations. Massey Ferguson delivers value pricing but maintains a smaller dealer network in some regions, potentially impacting service availability.

New Holland distinguishes itself through unique features such as adjustable shuttle aggression settings, as noted by Farmers Guardian. This customization allows operators to fine-tune transmission response for specific livestock handling tasks.

How Does Cost of Ownership Compare for Each Brand?

Cost of ownership varies across tractor brands based on purchase price, fuel costs, maintenance intervals, parts availability, and long-term durability. The New Holland T5.120 Dual Command with loader carries an MSRP of approximately $95,199.99. The T6.180 Methane Power reduces running costs by 30% compared to diesel competitors through alternative fuel technology.

Service intervals of 1,200-1,500 hours match or exceed competitor maintenance schedules, reducing downtime costs. Parts availability through major dealers like Messick's, maintaining 250,000+ piece inventories, ensures minimal equipment idle time. The North America tractor market grows at 3.30% CAGR, supporting strong resale values across major brands.

Progressive Farmer readers rated New Holland Most Durable in the midsize category, directly impacting long-term ownership costs through reduced repair frequency and extended operational life.

What Do Customer Reviews Say About New Holland Reliability?

Customer reviews consistently highlight New Holland's reliability in demanding livestock conditions. Progressive Farmer readers awarded New Holland the Most Durable tractor designation in the midsize category through direct user voting. Farmers report years of trouble-free operation even under intensive daily livestock management requirements.

H&R Agri-Power maintains a 4.9-star customer rating with reviews specifically praising equipment reliability and service quality. Ivan Wyeth reported zero problems with the T6.180 Methane Power model, confirming performance matches diesel tractors. Multiple testimonials document T5 and T6 tractors maintaining consistent performance over extended operational periods without major failures.

Riviera Produce expressed satisfaction with T6 Methane Power performance, stating it performs identically to diesel tractors while reducing operational costs. These real-world experiences from livestock and mixed-use operations validate New Holland's reliability claims across diverse farming applications.

What Maintenance and Support Options Are Available for New Holland Tractors?

Maintenance and support options for New Holland tractors include extended service intervals, nationwide parts availability, and comprehensive dealer support networks. New Holland's ECOBlue™ engines require maintenance every 1,200-1,500 hours, providing 25% longer intervals than previous generations. H&R Agri-Power operates 21 locations across six states, offering certified technician support and mobile service trucks for on-farm repairs.

How Easy Is Routine Maintenance on New Holland Tractors?

Routine maintenance on New Holland tractors is simplified through accessible service points and extended intervals. Standard maintenance occurs at 1,200-1,500 hours or annually, with ECOBlue™ engines extending service intervals 25% beyond previous generations. Engine oil, hydraulic filters, and air filters feature easy-access designs for quick changes.

The Top Maintain program locks in maintenance costs for predictable budgeting. New Holland-certified technicians perform scheduled services following manufacturer specifications. Regular inspection programs and preventive maintenance schedules minimize unplanned downtime during critical farming seasons.

Service accessibility reduces maintenance time and keeps tractors operational when farms need them most.

What Is the Availability of Replacement Parts and Service?

Replacement parts and service for New Holland tractors are widely available through national distribution centers, dealer networks, and online ordering platforms. New Holland maintains parts depots throughout the United States, delivering most components next-day or within 2-5 days for standard orders. Messick's stocks over 250,000 New Holland parts pieces ready for immediate shipment.

The MyCNH Store provides 24/7 online ordering with national shipping capabilities. H&R Agri-Power's 21 locations across six states ensure convenient parts access. Mobile service trucks bring repairs directly to farms, eliminating equipment transport requirements. There are multiple channels for parts acquisition, such as online platforms, physical dealerships, and mobile service options.

Parts availability and service accessibility ensure tractors return to work quickly after maintenance or repairs.

How Does Dealer Support Impact Farm Productivity?

Dealer support impacts farm productivity by maximizing equipment uptime, accelerating repairs, and providing expert technical assistance during critical seasons. The Top Service™ program guarantees equipment availability during busy seasons via comprehensive dealer network support. Fast parts fulfillment and personalized repair solutions reduce operational disruptions to farming schedules.

H&R Agri-Power employs manufacturer-trained technicians who maximize equipment productivity through proper maintenance. Emergency support operates 24/7 through dealer networks for critical situations. Precision Agriculture Specialists assist with technology integration, optimizing productivity through advanced features. H&R Agri-Power's employee-owned structure aligns dealer interests directly with customer success metrics.

Strong dealer support transforms maintenance from a disruption into a productivity enhancement tool for livestock and mixed-use farming operations.

How Can H&R Agri-Power Help You Find the Right New Holland Tractor?

H&R Agri-Power helps farmers find the right New Holland tractor by providing expert consultation, broad inventory access, and regional service support. The employee-owned dealership network spans six states with mobile service capabilities reaching farms directly. Their certified technicians match specific livestock and mixed farming requirements to optimal tractor configurations.

What New Holland Tractor Solutions Does H&R Agri-Power Offer for Livestock and Mixed Use Farms?

H&R Agri-Power offers comprehensive New Holland tractor solutions including the full T4 (58-75 HP), T5 (93-111 PTO HP), and T6 (95-126 PTO HP) series inventory. Expert sales consultants analyze unique operational needs matching equipment specifications to farm requirements. The dealership stocks LA Series Front Loaders with Quick-Attach™ systems for efficient feed and manure handling transitions.

Technology integration services include FieldOps™ real-time monitoring setup and PLM Intelligence™ precision agriculture implementation. H&R Agri-Power provides flexible financing options with competitive rates tailored to different equipment types and farm budgets. Mobile service trucks deliver on-farm support minimizing equipment transport requirements across their six-state territory.

What Are the Key Takeaways About the Best New Holland Tractors for Livestock and Mixed Use Farms?

The key takeaways about the best New Holland tractors for livestock and mixed use farms are performance specifications, operational efficiency, and regional support infrastructure. T5 Series tractors deliver 93-111 PTO HP with 444 Nm torque at 1,500 RPM for optimal livestock operation balance. T6 Series provides 145-180 max HP with loader lift capacities exceeding 2 tons for versatile mixed farming applications.

Auto Command™ CVT transmission technology eliminates clutch and brake use reducing operator fatigue during extended operations. Progressive Farmer readers rated New Holland Most Durable in the midsize tractor category based on field performance. T6.180 Methane Power models achieve 30% lower operating costs than diesel equivalents for sustainable farm economics. H&R Agri-Power's 21-location network ensures comprehensive sales consultation, certified service, and parts availability throughout the region.